WOOD-GAS TECHNOLOGY

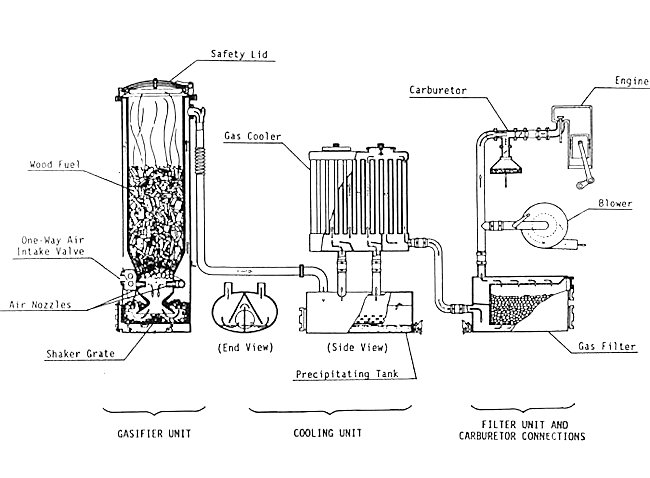

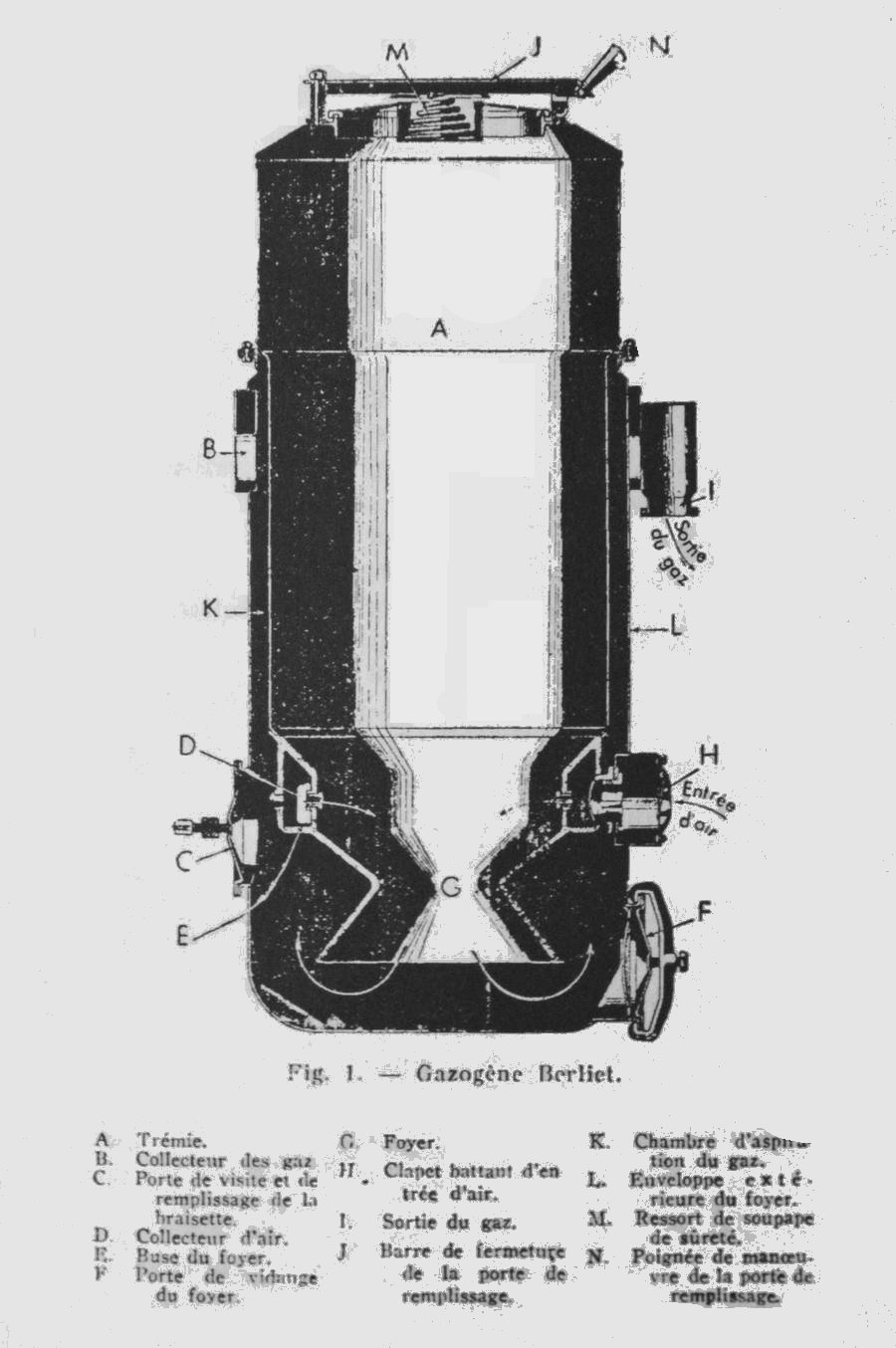

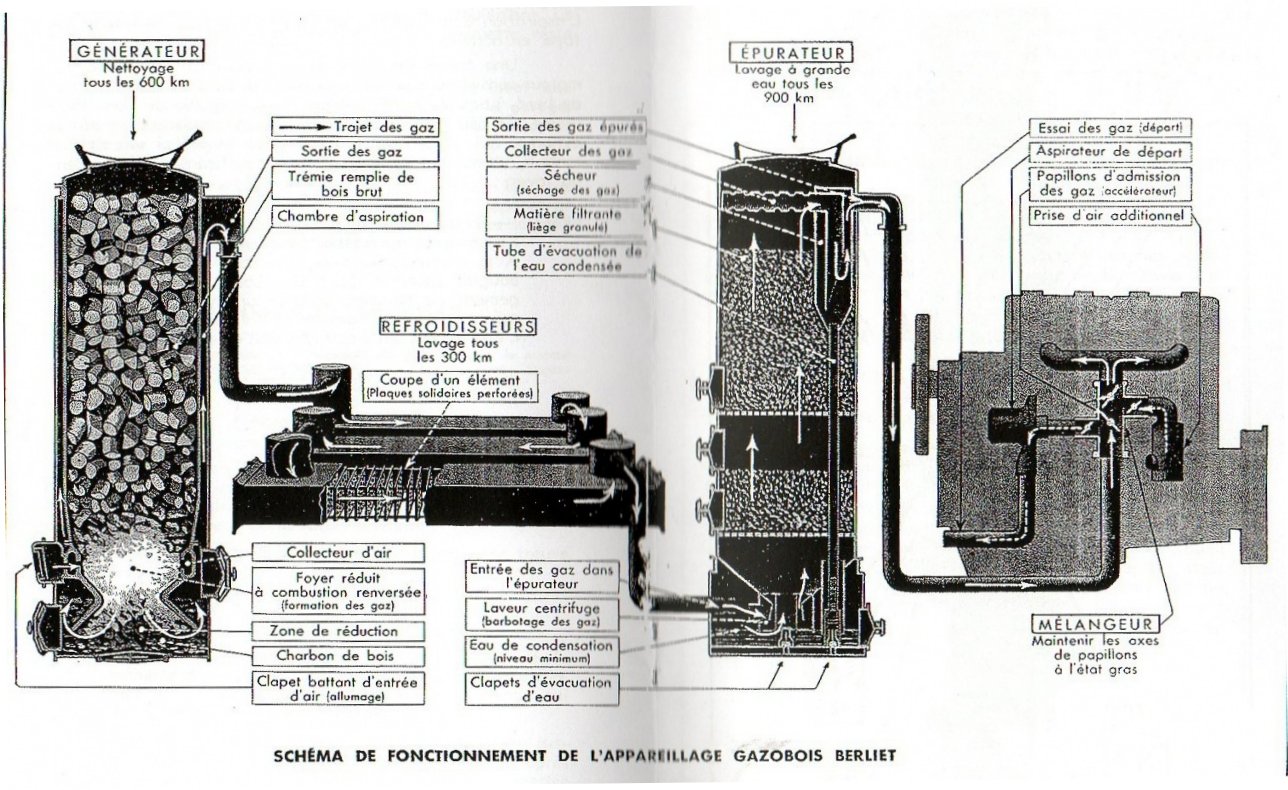

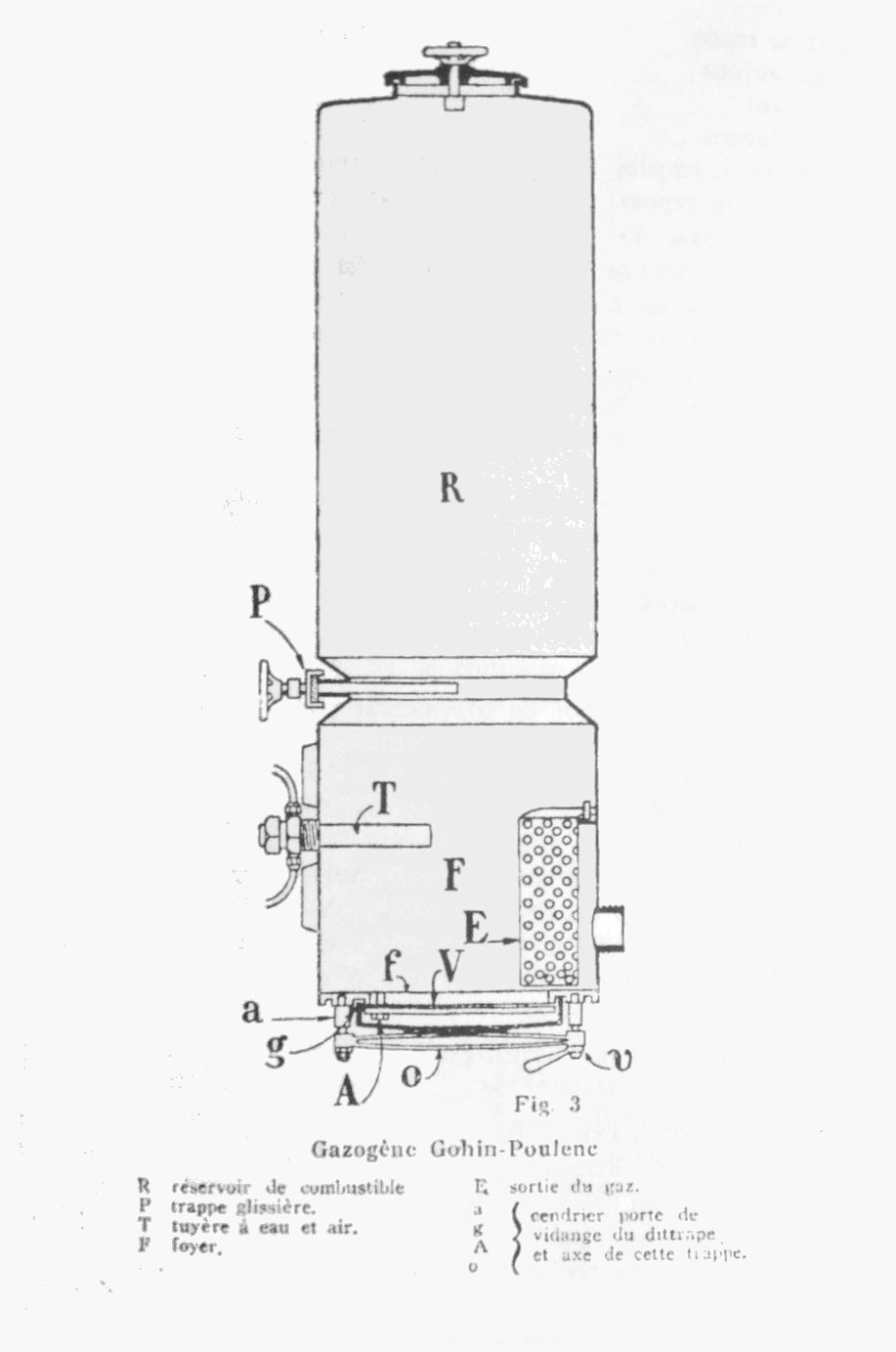

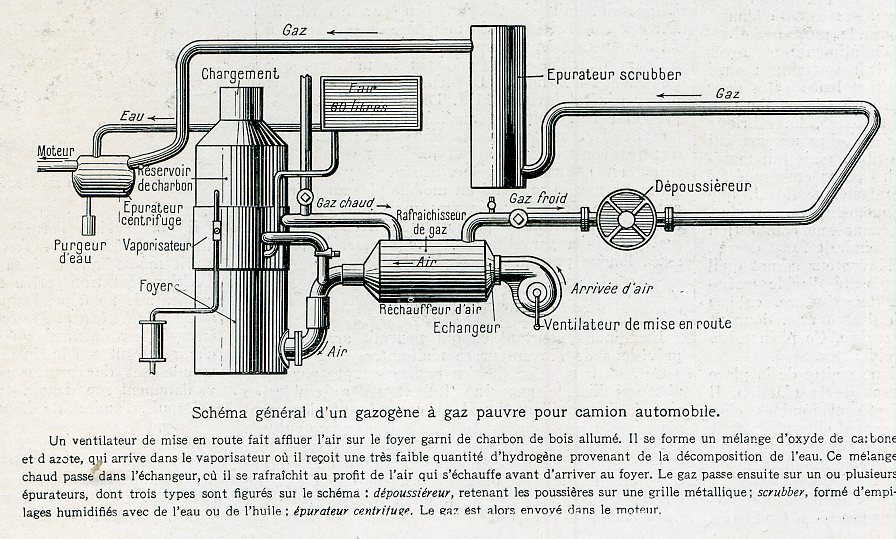

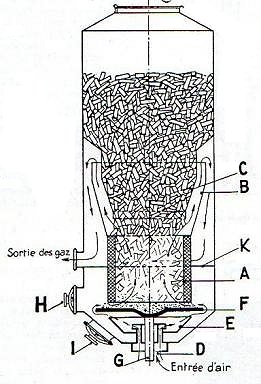

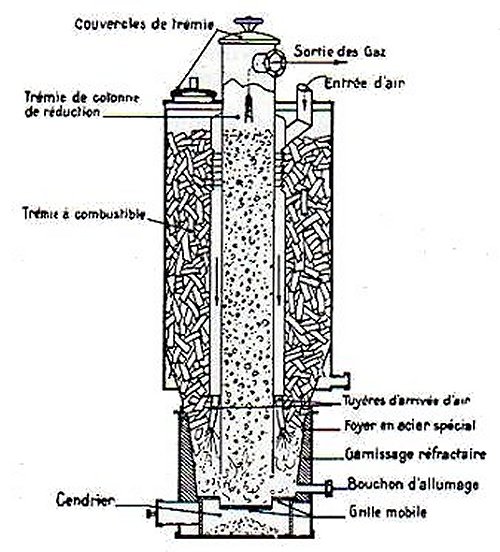

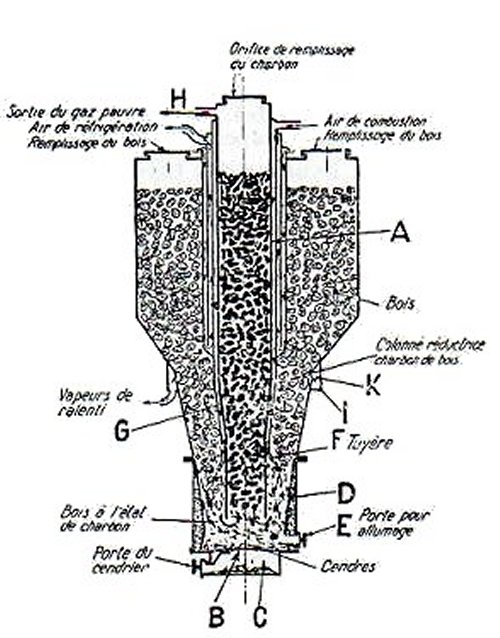

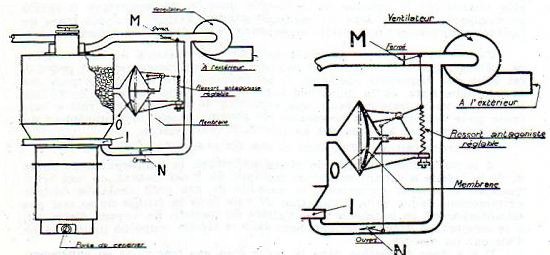

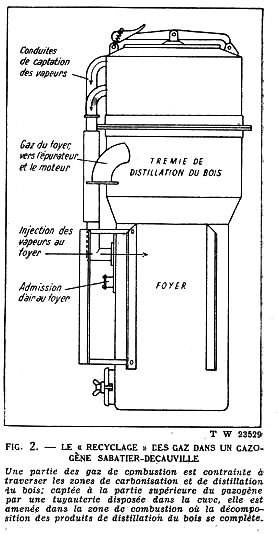

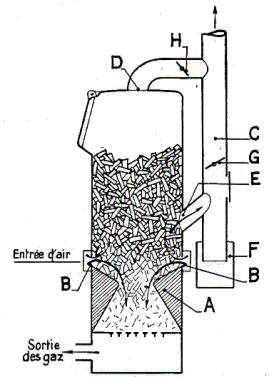

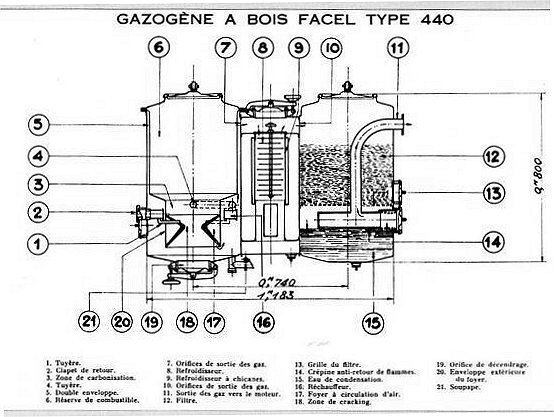

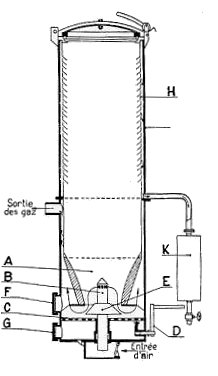

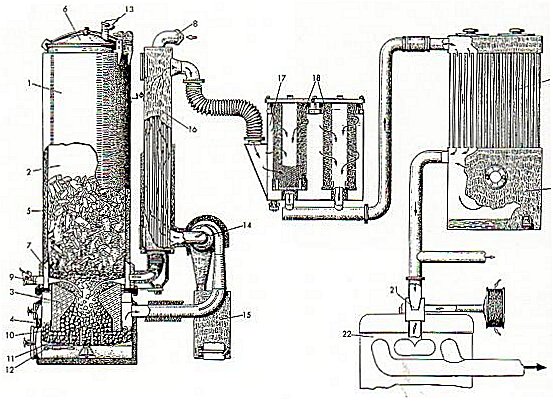

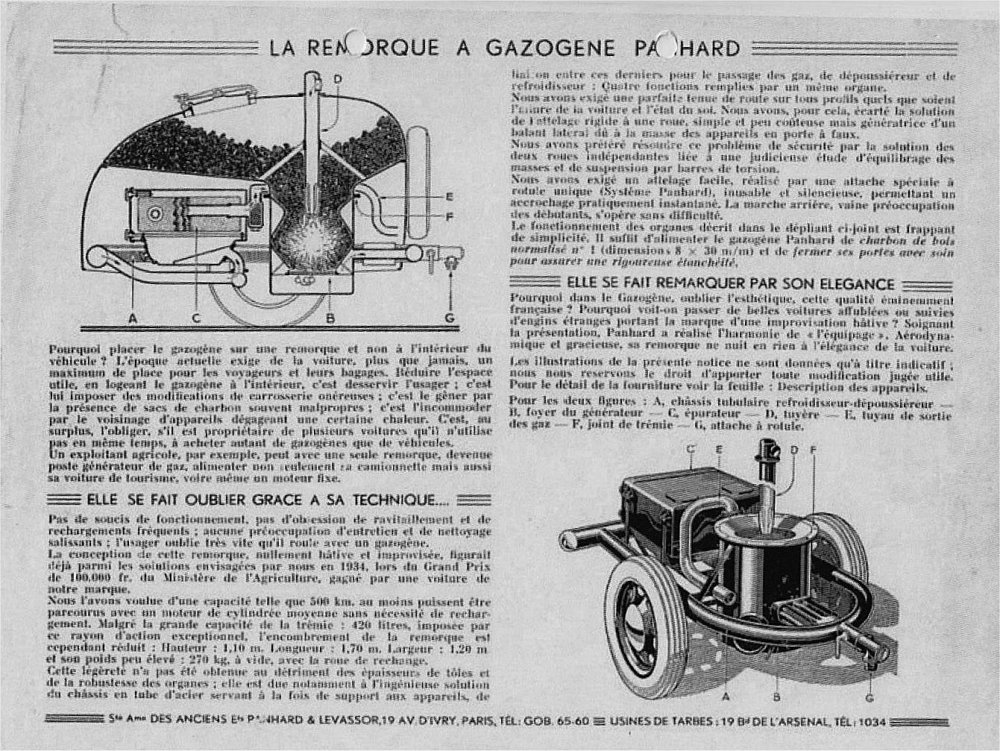

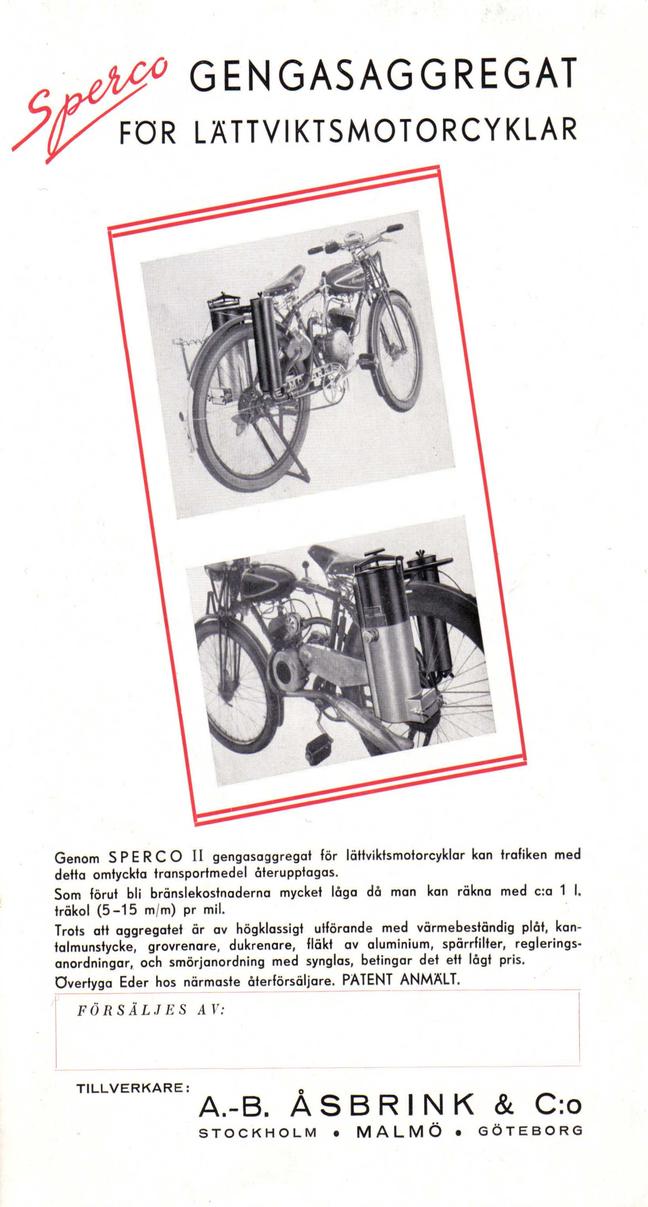

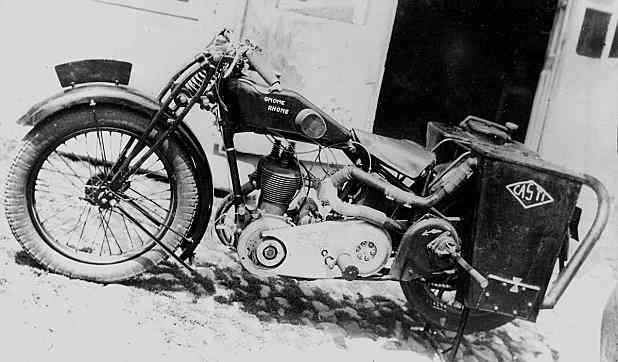

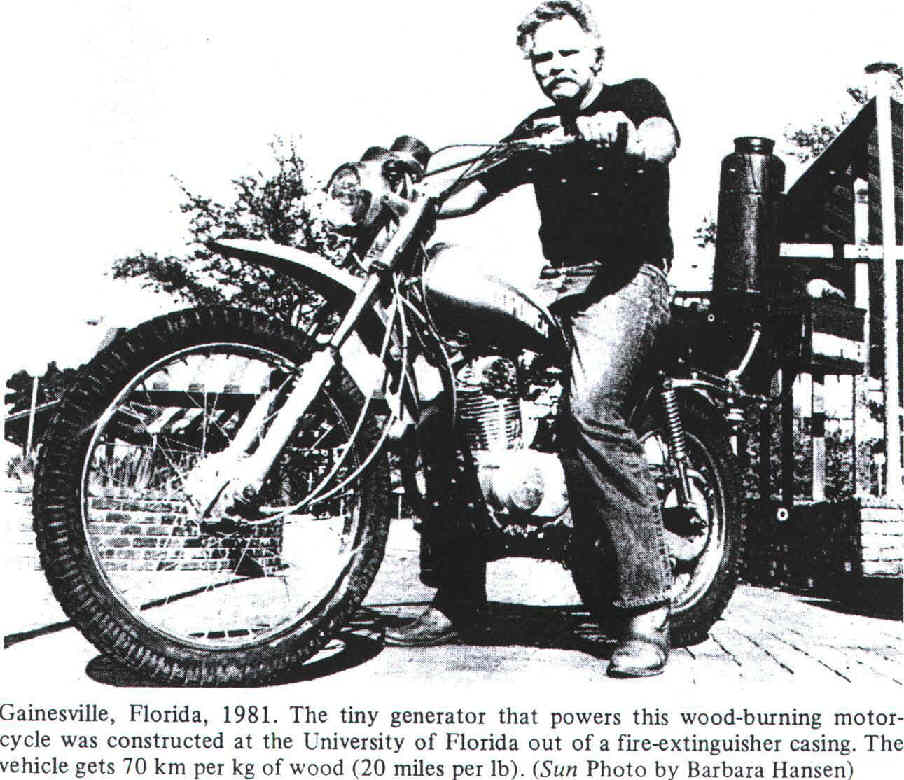

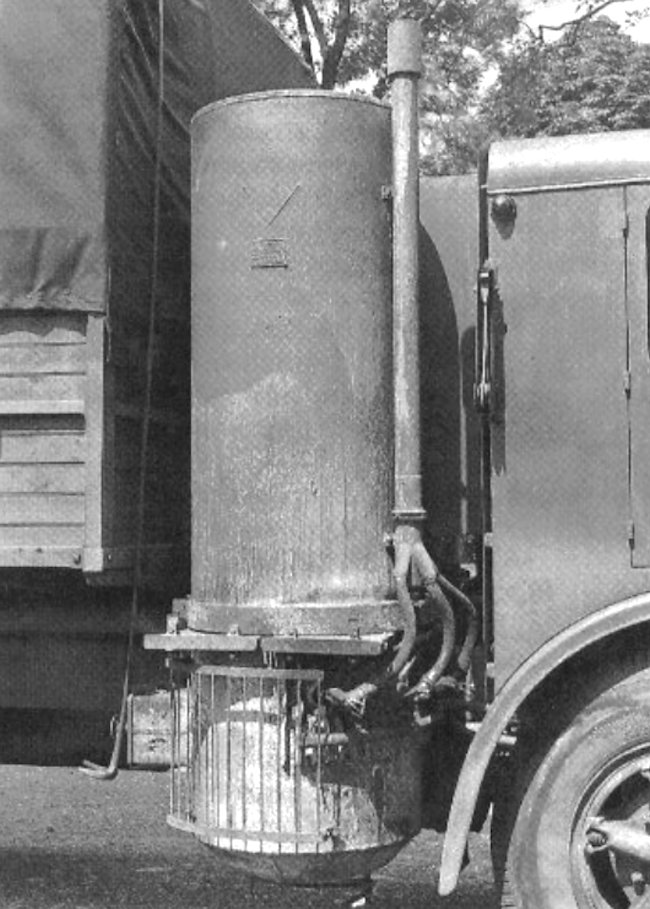

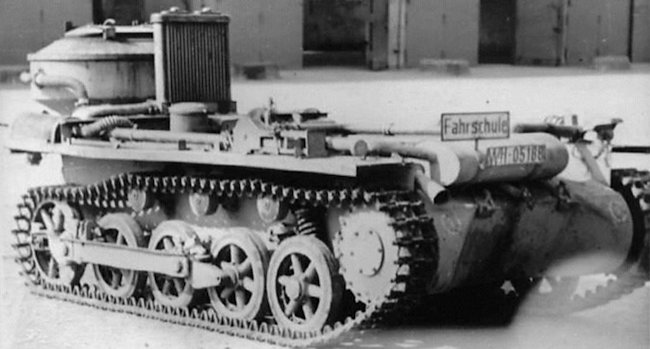

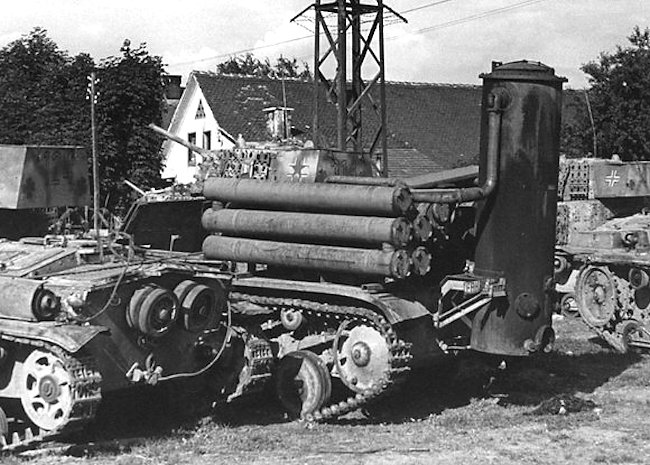

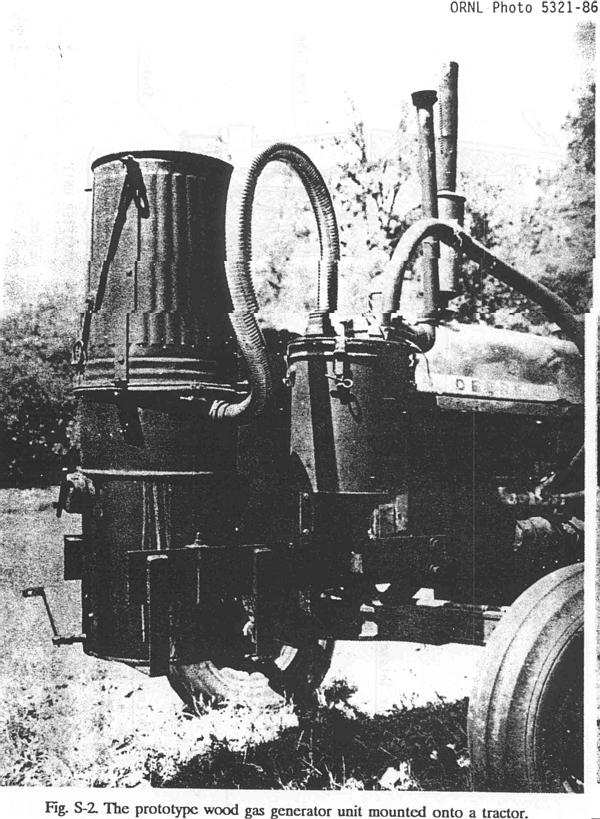

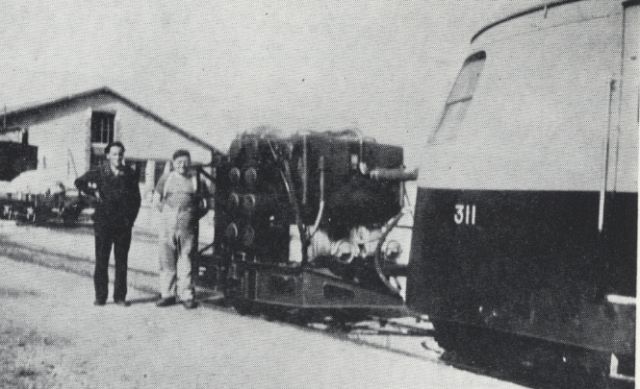

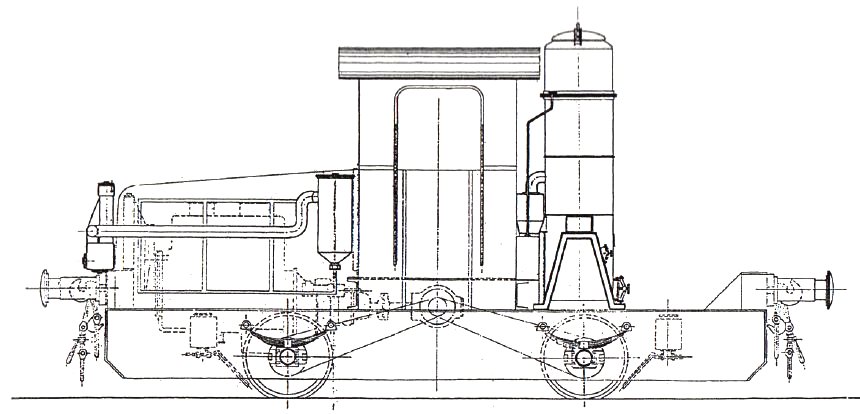

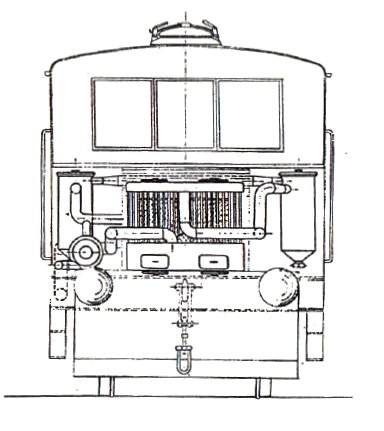

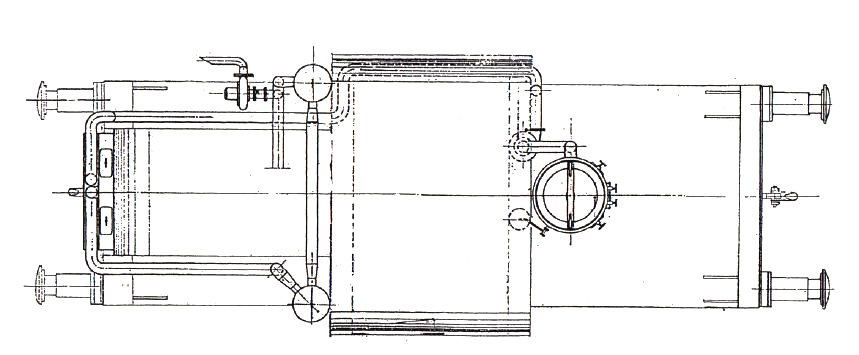

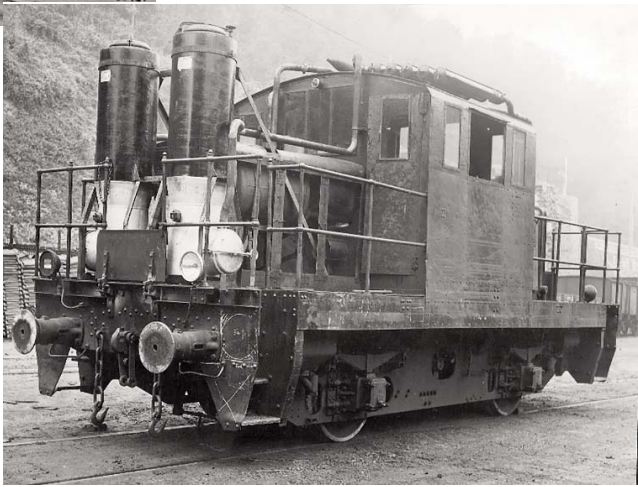

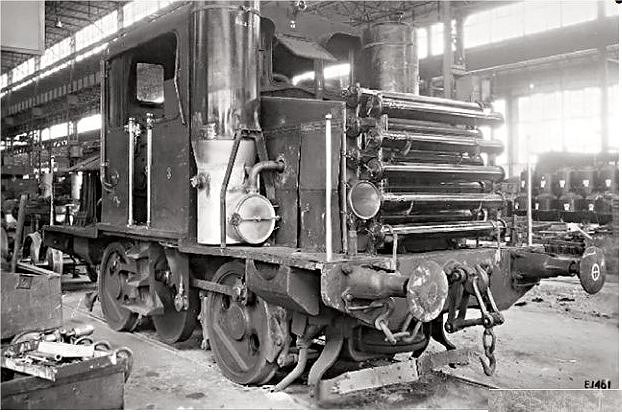

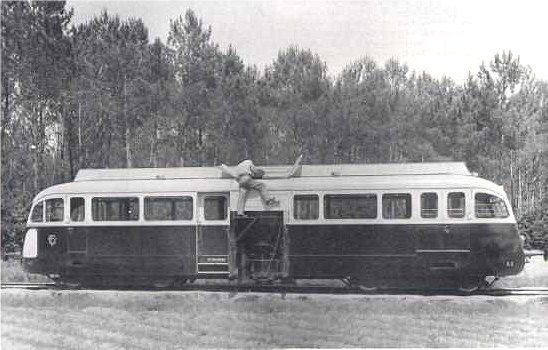

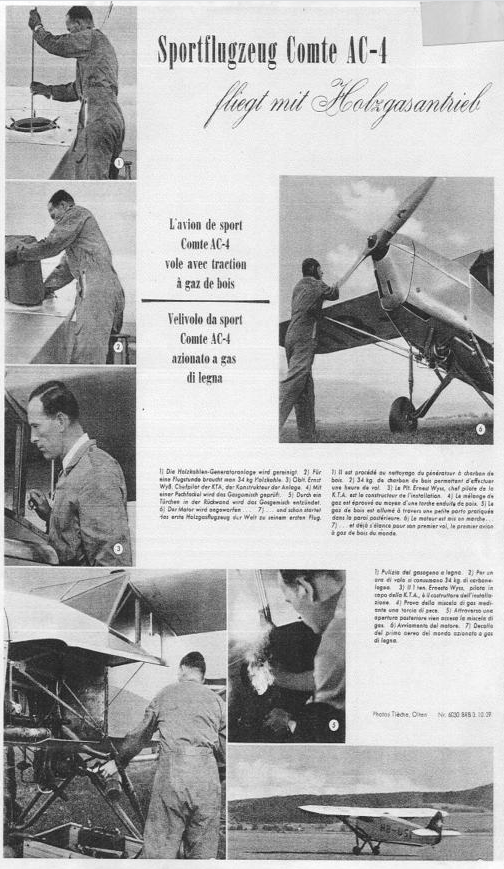

In the absence of oil, people turn to desperate measures to move themselves and their stuff around. Vehicles running on wood-gas carry around a plant for the gasification of wood, which is done by heating wood pellets, or similiar organic materials, to high temperatures in a closed vessel with a limited amount of oxygen. The heating, which can reach a temperature of 1400 °C, is done by partial combustion of the wood pellets. The wood-gas given off contains hydrogen and carbon monoxide, which can be used in an IC engine with only minor modifications. The history of wood gasification goes right back to the 1870s, when it was used instead of coal-gas for street lighting and cooking.

Wood-gas consists very roughly of 50% nitrogen, 8% carbon dioxide, 20% carbon monoxide, 18% hydrogen, and 4% methane. The nitrogen and carbon dioxide that make up 58% are of course inert as far as the engine is concerned; it is a low energy-density fuel. It however must be mixed with air to make it combustible, and this adds even more inert nitrogen. Thus the power output from an engine is much reduced when it runs on wood-gas rather than petrol.

Be aware that producer gas can also refer to gas produced by the gasification of coal or anthracite. It may also refer to water-gas, which is produced by a modified process by which adds the injection of water or steam to obtain a higher heat content gas with a higher hydrogen content; it is a particularly dangerous variant as it contains large amounts of hydrogen and carbon monoxide, making it both explosive and very poisonous. Some wood-gas systems used water injection to get better gas, but this also takes heat out of the process, and in most cases seems to have been regarded as an undesirable complication to an already awkward system.

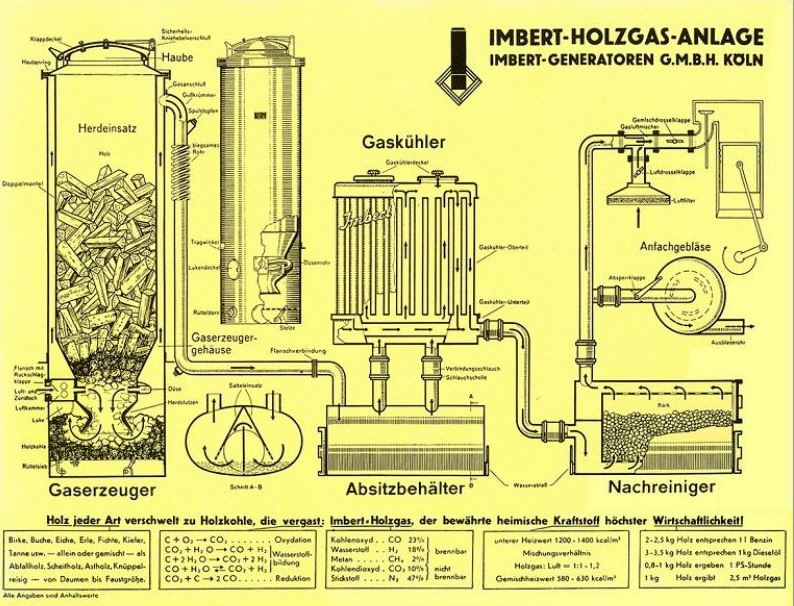

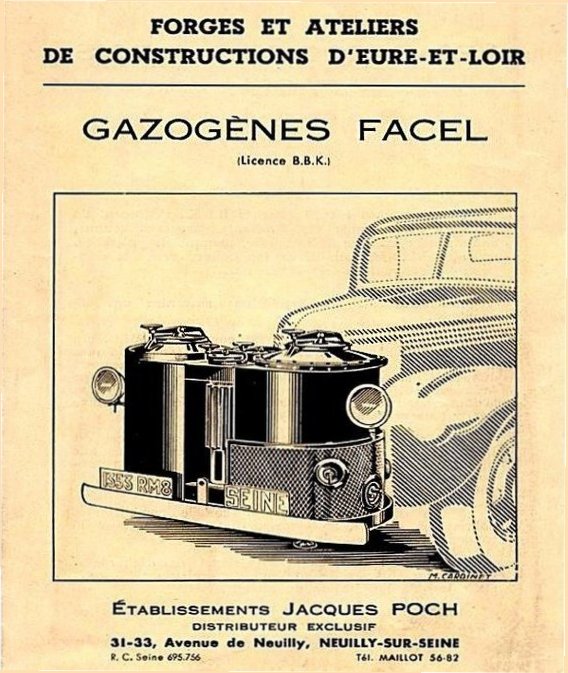

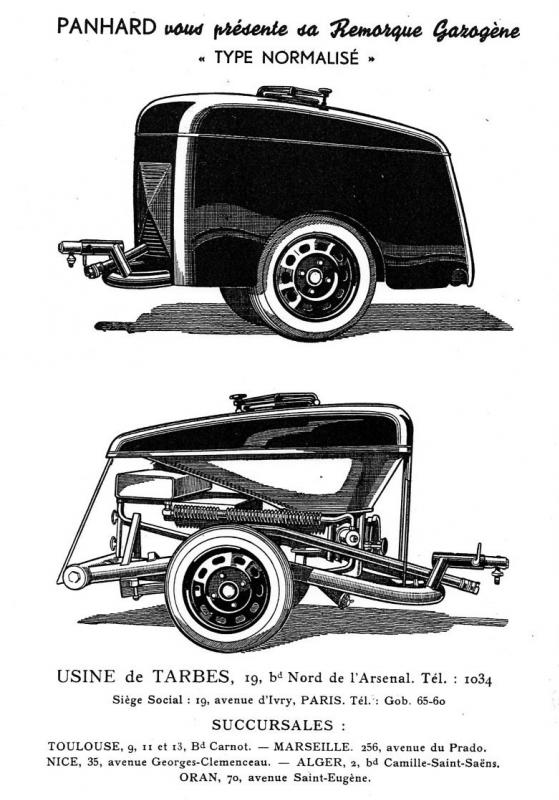

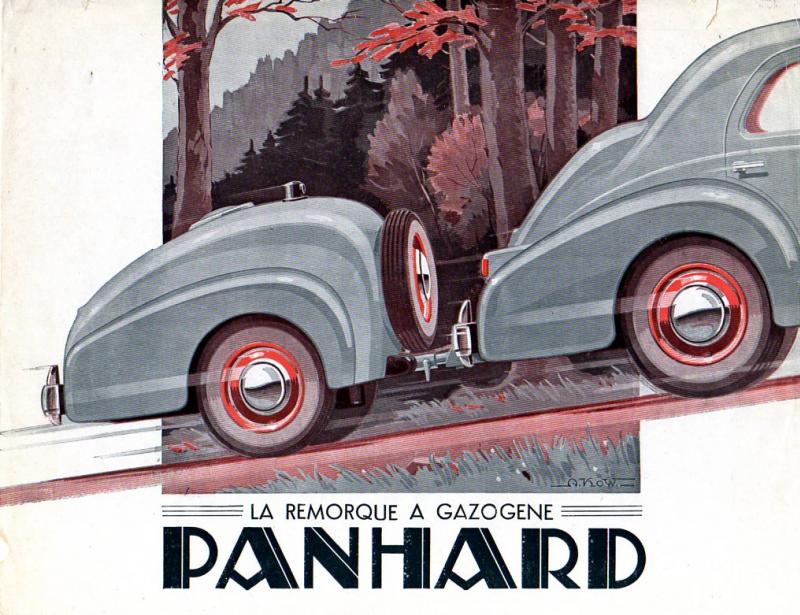

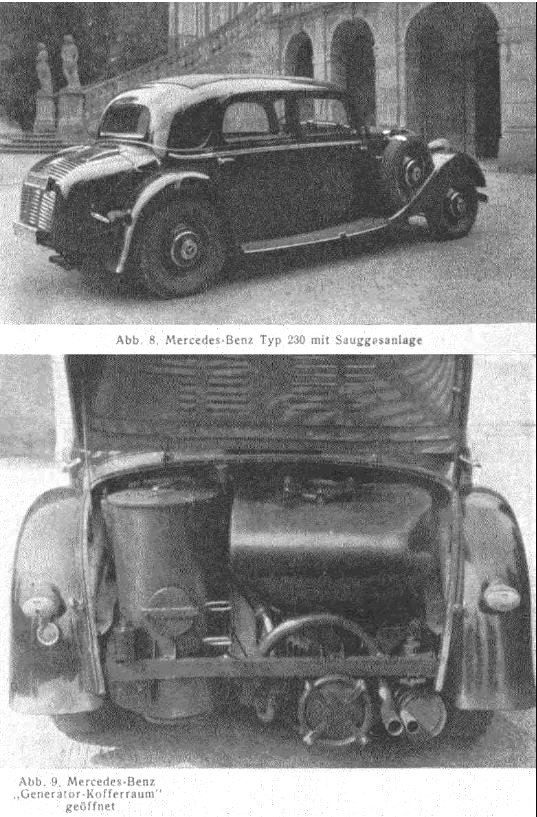

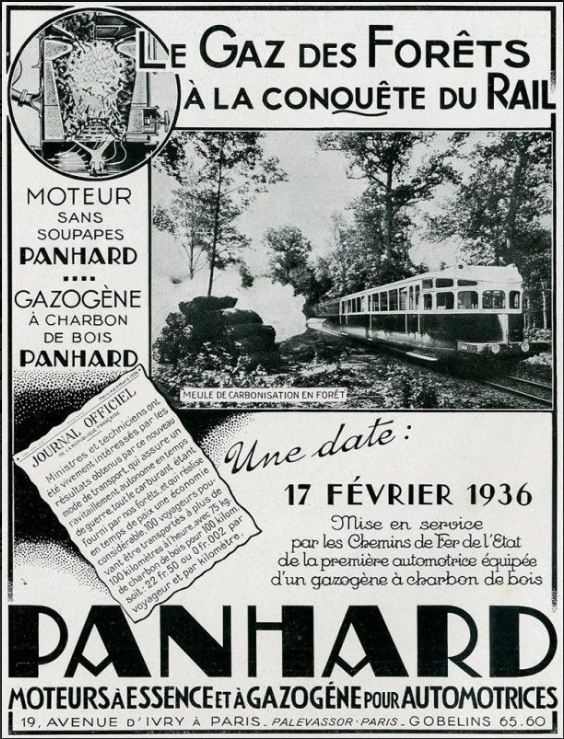

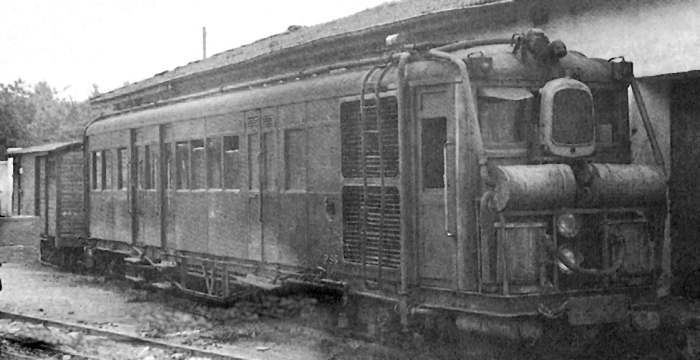

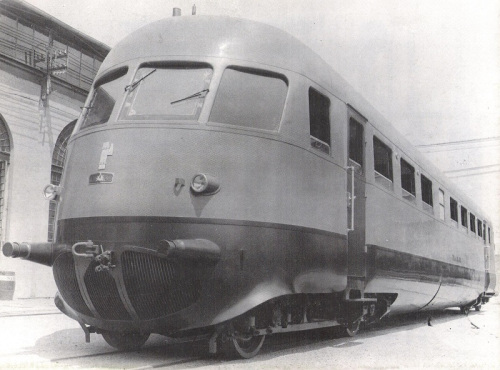

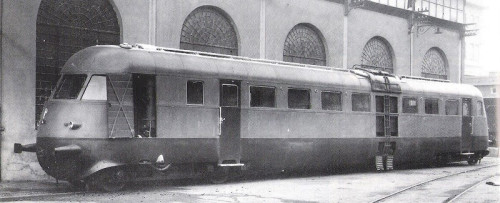

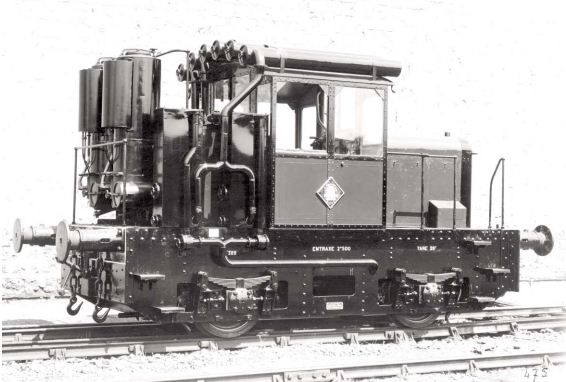

In the 1920s, the French (Not German) engineer Georges Imbert developed a wood-gas generator for mobile use. The wood-gase was cleaned and cooled and then fed into the vehicle's engine. The Imbert gas generator was mass produced from 1931 on. At the end of the 1930s, about 9,000 wood gas vehicles were in use, almost exclusively in Europe.