Gallery opened 8 Apr 2020

Updated 18 Nov 2023

Coal gas boat updated here

Coal-gas Powered Vehicles |

Gallery opened 8 Apr 2020 |

Cars running on LPG (Liquefied petroleum gas) are not especially unusual. This page deals with vehicles specifically running on coal gas. (also called town gas)

During war-time it can be useful to be able to run vehicles on coal gas (also known as town gas, which contained hydrogen, carbon monoxide, methane, and ethylene) because it's made from, well, coal rather than oil, which tends to be in short supply. Typically it was carried around in a gas-bag mounted on top of the vehicle. The gas-bag was made of fabric, made gas-tight by some sort of coating, such as rubber solution.

I have seen it written in more than one place that said that carbon monoxide, in particular, cannot be compressed into steel cylinders, which would be much more handy than big gas-bags, because it would explode. This is completely untrue, and is probably a confusion with acetylene, which most certainly will explode when compressed. This site has some info on compressed carbon monoxide. The people here appear to have subjected carbon monoxide to shock compression to 90 GPa (900 kbar) with no mention of explosions.

I strongly suspect the real reason is that gas cylinders were rarely used is that their manufacture requires quite a lot of high-grade steel, which in war-time will probably be required for rather more important applications. That also makes them relatively expensive compared with a gas-bag. Gas cylinders are of course also rather heavy compared with a gas-bag, and that alone might have doomed the idea. It did see some use in France.

The gas-bags were made of fabric coated with rubber to make it (more or less) gas-tight. The pressures were inevitably low, partly because of the limited mechanical strength of the gasbag material, but also because hydrogen, which is an important constituent of coal-gas, (typically 50%) will diffuse through pretty much anything, including solid steel.

The extremely specialised subject of gasbag motorcycles is already exhibited in The Museum.

COAL-GAS POWERED CARS

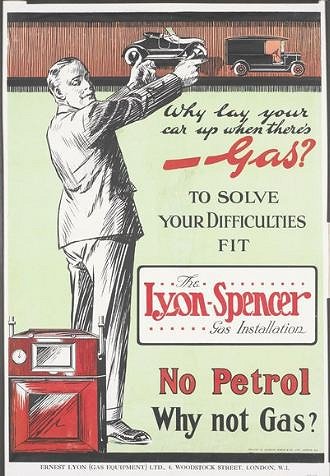

| Left: Advert for coal-gas power: WW1?

|

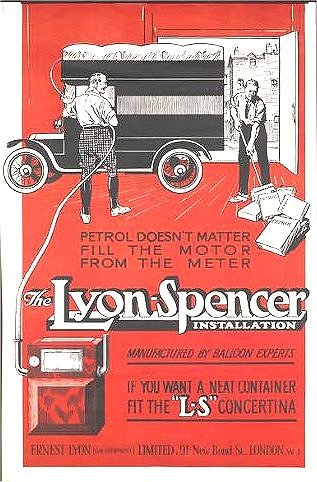

| Left: Advert for coal-gas power: WW1?

|

| Left: Two cars with gas storage bags on the roof: WW2

|

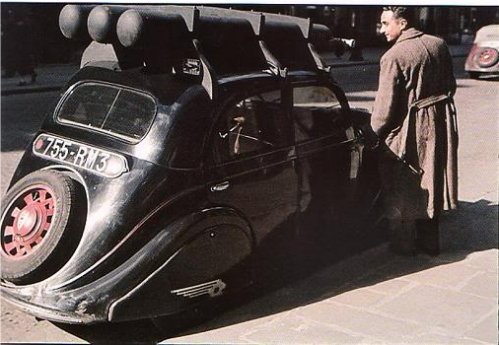

| Left: Car with gas storage bag on the roof: WW2

|

| Left: Car with gas bag on the roof AND a towed gas generator: WW2

|

| Left: Car with gas storage cylinders on the roof: WW2

|

| Left: Car with gas storage cylinders on the roof: WW2

|

COAL-GAS POWERED BUSES & TRAMS

|

|

|

|

|

| Left: Gas-powered tram in Morecambe: 1918

|

This description of the Morecombe tram conversion comes from The Commercial Motor for 29th August 1918:

"Several departures from standard motorcar practice were adopted in designing the cars, but the power unit is practically identical with the 55 h.p. four-cylinder engine fitted to the Leyland fire-engine. The cooling system works from both ends of the car, a radiator being placed to face the front, which ever way the car is travelling. The transmission has naturally undergone revision, hut there are some points of resemblance with that of the five ton lorry. The gearbox is modified from standard to permit of the use of all four speeds in either direction, power being transmitted to one axle by-a double reduction spur gear enclosed in an oil-tight casing with a central, enclosed propeller shaft. There is also a heavy roller chain provided from axle to axle to distribute the drive, the chain performing the functions of the side connecting rods of the ordinary railway locomotive. As there is a straight run and return on the track, and the cars are reversed at the end of the journey, double controls are provided, but the control not required is thrown out of action by simply extracting a locking pin when the driver leaves one end.""With the beginning of this year, on the approach of the holiday season, and faced with the difficulty of not being able to keep the cars on the road when the rush of passengers presented itself, the directors of the company resolved to supplement their allowance of petrol by converting three of the four cars to coal-gas. One car is of the open "toast-rack" pattern, and to fit a gas container to this would be a difficult matter. But, with. the three covered cars, a boxwork fitting has been erected on the roof, as will be seen from the illustrations on previous page. This extends practically the full length of the car and is of considerable depth. Inside, and with its flaps strapped to the woodwork, is the gas container of a capacity of nearly 900 cu ft. The containers were manufactured by Messrs. John }Ina-pc and Sons Ltd; Burnley, and are among the largest gas containers in existence. When full they extend somewhat above the wooden framework, but when the charge of gas is partially exhausted the generous size of the solid framework prevents flapping. Filling is done at the sheds, a specially made pipe of fabric being run out of the depot and the car filled in the yard as a safeguard against fire. The filling pipe from the meter connects with a wrought-iron pipe with a screw connection, which comes out of the box portion of the container and finishes level with the canopy. Through this pipe gas is supplied to the container, and, when filling is completed, a valve is closed at the base." "Gas is drawn to the engine through a length of flexible metallic tubing which is connected to the filling pipe immediately above the valve, find carried down to the carburetter. On the new fuel, with the engines being well up to their work, ample power is provided. There are no overhanging obstructions on the route, and, consequently, the additional height is no disadvantage. By an occasional use of petrol when the charge of gas is exhausted and a refill at convenient times—generally when the drivers are having meals during a quiet part of the day—an efficient service can now be maintained. Eight double journeys, 1.1 miles each way can be performed on one charge of gas, and thus a service probably as cheap as any in the country is maintained." |

So it appears the gas-tram could do 8 x 2.5 = 20 miles on one bag of gas, which was enough. NB: Paul Burke pointed out to me that the original figure of 11 miles each way was an OCR glitch in the text, and the true length was 1.25 miles.

COAL-GAS POWERED LORRYS

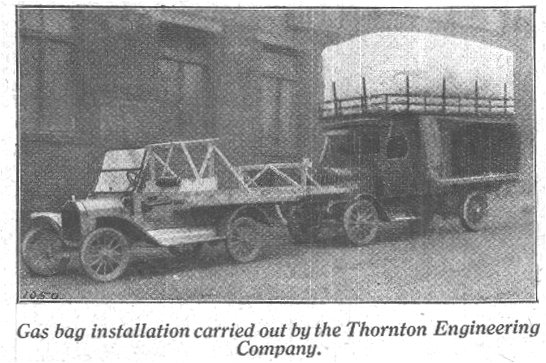

| Left: Lorry with gas-bag storage: WW1

|

COAL-GAS POWERED TANKS

| Left: Panzer V Panther Tank with cylinder coal-gas storage: WW2

See the Museum page on Wood-gas Vehicles. |

| Left: Panzer V Panther Tank with cylinder coal-gas storage: WW2

|

| Left: Panzer V Panther Tank with cylinder coal-gas storage: WW2

|

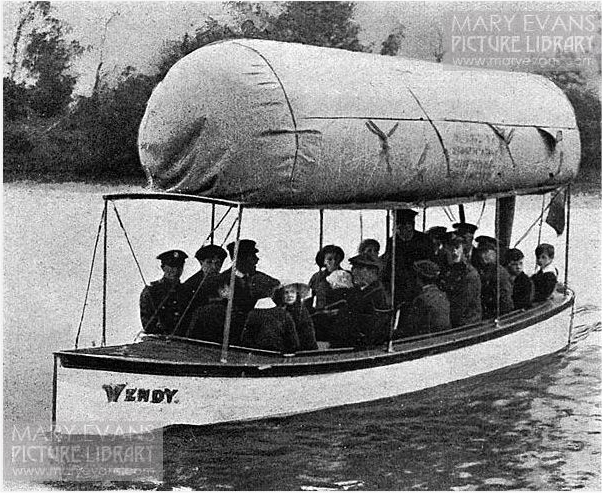

| Left: Boat with gas-bag storage: WW1

|

COAL-GAS DISTRIBUTION

From the Commercial Motor for 21st March 1918, page 17:

Novel Gas Bag Coupling. |

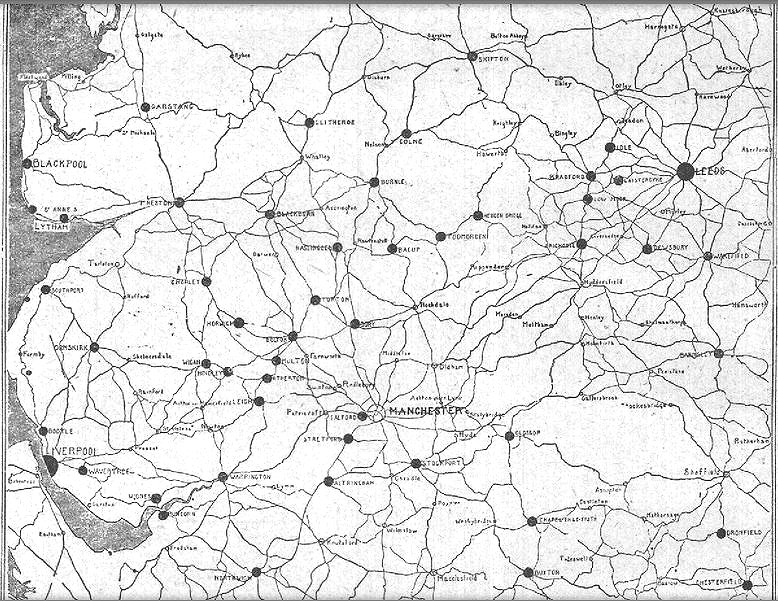

| Left: Map of coal-gasrefuelling points: WW1

"We reproduce herewith the map showing the coal-gas charging stations which are to-day available to motor vehicles running on this fuel, within a radius of 40 miles of Manchester. The preparation of this highly useful reference is due to the enterprise of Messrs. Brannen and Co, 43 Edgehill, Shudehill, Manchester, who it may be recalled have carried out many gas installations upon commercial vehicles of all descriptions. The map is produced upon such a scale as to give four miles to one inch, and the area embraced is to Leeds, Barnsley, and Chesterfield, on the east; Ashbourne, Stoke-on-Trent and Wrexham on the south; Liverpool, Morecambe and Blackpool on the west; and Lancaster and Skipton on the north." |

"At Glasgow Corporation Gas Committee the manager reported difficulty in getting petrol for the motor vans, and he was authorized to purchase two of the latest Lyon-Spencer type of gas containers."

"Ploughing on Gas at Nottingham.

The interesting experiment which has been conducted near Nottingham with coal-gas power for tractors, and to which we referred recently in The Commercial Motor, has aroused interest. So far as the fuel cost of the system is concerned, we learn that this comes out at a very low figure. To our mind it should be possible to accomplish an appreciable amount of tractor ploughing on gas, more particularly when the fields are in relatively close proximity to the village gas works. These undertakings for the most part are in the position to supply gas of high quality for the simple reason that they are not called upon to strip their gas. In such districts the gas being richer than that available in town, should give higher mileage or work per 250 cubic ft."

|