Gallery opened: Nov 2007

Last update: 30 March 2013

Updated: 21 Jan 2020 Radial steam engine in a propellor

Radial Steam Engines |

Gallery opened: Nov 2007 |

Radial steam engines have three or more cylinders arranged at an equal spacing on a circle around the crankshaft. The cylinders stay still while the crankshaft revolves; this may seem a crashingly obvious statement but there were such things as rotary engines, in which the crankshaft stayed still and the cylinder assembly revolved around it. These should not be confused with the other sort of rotary engine, in which some kind of a piston rotated in a fixed housing.

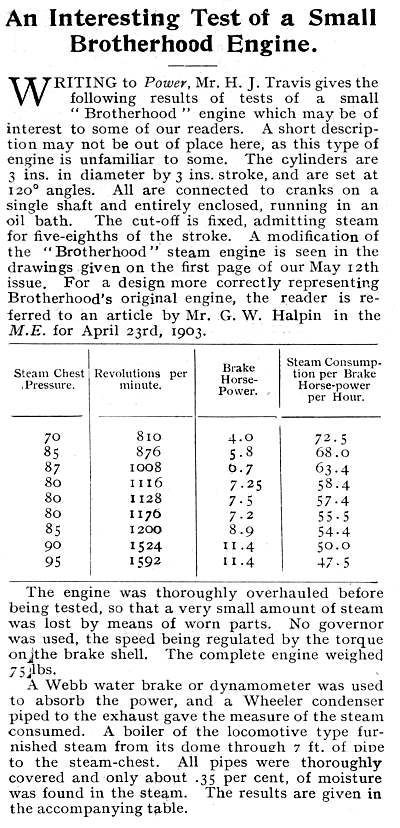

THE BROTHERHOOD RADIAL ENGINE

The Brotherhood engine was a popular and successful three-cylinder radial design that was adapted for various operating fluids. A large number were used as water engines, for driving hydraulic capstans in docks and so on, but they were also widely used as steam engines. Versions for steam use are shown here; it is notable that the steam versions show considerable design differences from the water-driven version.

| Left: The Brotherhood Radial Engine: axial section

|

| Left: The Brotherhood Radial Engine: longitudinal section

|

| |

Above: The Brotherhood Radial Engine: alternative valvegear

|

| Left: The Brotherhood Radial Engine: account of a test

|

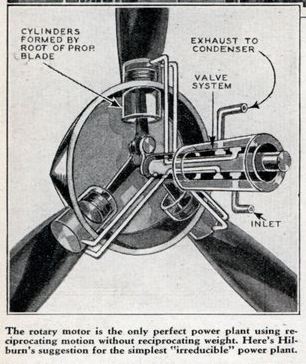

A RADIAL ENGINE IN A PROPELLOR

| Left: Captain Richardson's radial steam engine in a propellor: 1932

|

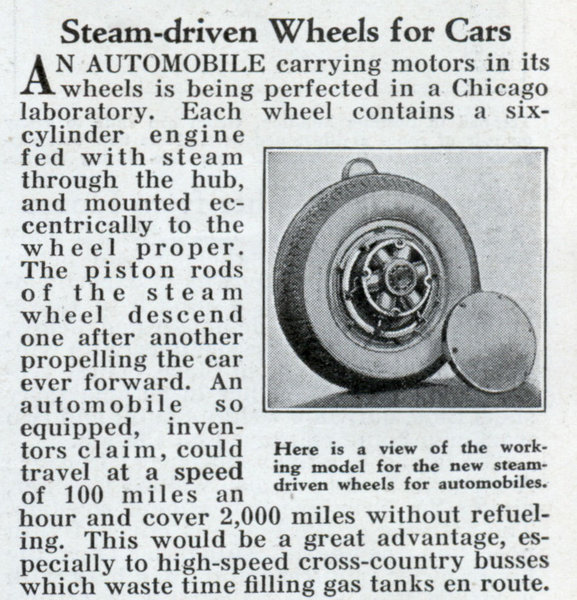

A RADIAL ENGINE IN A WHEEL

| Left: Radial steam engine in a car wheel: Dec 1932

|

|