Updated: 2 Apr 2015

More information overall

Engine pic added

Modelling added

Engine pic added

Modelling added

Powered by Boiling Petrol |

Updated: 2 Apr 2015

Engine pic added Modelling added |

|

Incredible as it may seem, around the end of the nineteenth century, small boats really were powered by boiling petrol and using the vapour to drive a sort of "steam" engine. The "petrol" was more often called "naptha" at the time, and was a mixture of low-boiling point hydrocarbons distilled directly from crude oil rather than the sophisticated brew we know as "petrol" nowadays. The literature of the day used both terms pretty much interchangeably, and I have done the same here.

The naptha was boiled by burning a certain proportion of the working fluid, ie naptha. At first I thought that the designs below were merely optimistic proposals, but further research has shown that "naptha launches" really did exist in significant numbers. However they appear to have been exclusively recreational craft for the rich rather than working boats.

I initially thought that naptha was adopted as a working fluid because it boiled at a lower temperature than water, and so was thought to be more efficient. (This is the exact opposite of the truth thermodynamically, but let's not get into Carnot's Law just here; see the thermodynamics page) The real reason, at least in the case of the Ofeldt boat, was quite different. It was simply to get round a law that required every steam-boat to carry a licensed steam engineer. Another motivation was that they could get up working pressure faster than a steam engine. Also, since the working fluid was the fuel, there was no need to carry separate supplies, while a steam launch had to carry both fuel and fresh water.

THE YARROW ZEPHYR: 1888

As reported in the French journal Nature for 21 July, 1888.

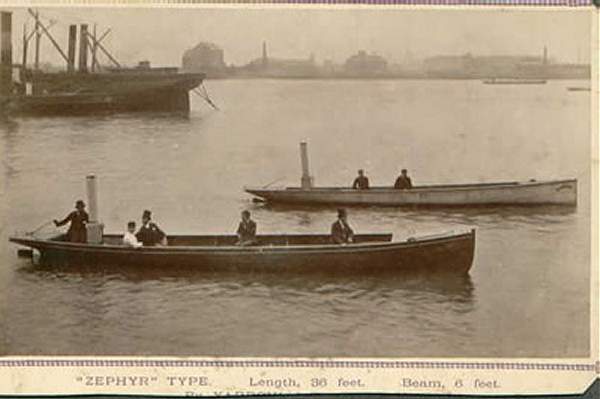

The launch Zephyr was the first boiling petrol boat. It was built by Mr Yarrow of London, who gave a talk on its design before the Institute of Naval Architects. Its length was 11 metres and the beam was 1.8 metres. It carried 40 gallons of petrol, which was both the fuel and the working fluid. The petrol vapour from the engine was recondensed in longitudinal chambers on each side of the hull.

| Left: The Zephyr Boiling-Petrol Launch |

The machinery and operation of this vessel appears to be very similiar to that of the Ofeldt launch described in detail below, and I will not describe it again here. The latter design is apparently not as original as I once thought.

One of the advantages that Mr Yarrow claimed for his power plant was that it could be started from cold in only five minutes. Nature made it very clear that they understood that reducing the operating temperature range would reduce cycle efficiency, not increase it, as one might at first suppose.

| Left: Two Zephyr-type launches

|

THE ESCHER WYSS NAPTHA LAUNCH: 1890

From the French journal Nature for 21 July, 1888.

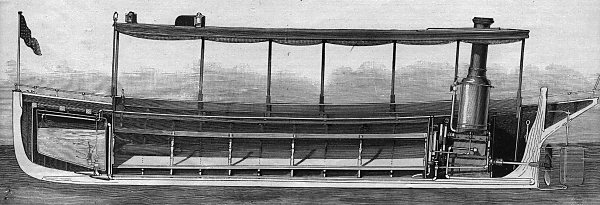

| Left: The Escher Wyss Boiling-Petrol Launch.

|

The Swiss firm of Escher Wyss built naphtha launches. One of these was Alfred Nobel's graceful aluminium-hulled sloop Mignon, built in 1892. Another, also of aluminium, was the Aluminia, built in 1894.

The exact relationship between the Yarrow Zephyr, Escher Wyss, and Ofeldt is not currently clear.

The company of Escher Wyss still exists, as a moment's Google will demonstrate.

THE OFELDT BOILING-PETROL LAUNCH: 1897

This section shows the bizarre and frightening arrangements of the Gas Engine and Power Company of Morriss Heights, 185th St, New york City. It was called the Essh system; that may be some sort of contraction of "Escher Wyss".

Frank W Ofeldt was a native of Sweden, according to his obituary, though the journal MotorBoating (Nov 1942, p46-48) said he was German. He was backed financially by Jabez A Bostwick, owner of the steam-yacht Orienta (built by the Herreshoffs) who was wealthy and associated with Standard Oil. The Gas Engine and Power Company was set up at 131st Street and Brook Avenue in New York. Clement a Gould was hired as manager; he was a relative of Bostwick. Ofeldt seems to have fallen out with the company sometime around 1888, for he left and began making his Alco-Vapor engines, which boiled a mixture of water and alcohol. This time he was backed by E C Benedict, owner of the steam-yacht Oneida. Tis association does not seem to have lasted long and Ofeldt turned his attention to kerosene intenal-combustion engines. Mr Olfeldt was clearly an enterprising man. Details about him are scarce, but here is his obituary:

"Frank W OFELDT - The Rev. Dr. H. C. A. Meyer of St. James Lutheran Church, conducted the funeral services today over the remains of Frank W Ofeldt at his late residence, 173 Twenty-third street. Mr. Olfedt died on Wednesday. He was 68 years old and was a native of Sweden. He was the inventor of the first naphtha launch and the first alco-vapor launch. He was engaged with his sons, Frank and Ernest, in building automobiles and launches at the foot of Twenty-fifth street. (ed: in Brooklyn) Two other sons, Walter and George, also survive him. The interment was in Greenwood Cemetery."

The Ofeldt company also built a few steam cars in Brooklyn, NY from 1899 to 1900 and Newark, NJ from 1901 to 1902. Serious automobile production was not undertaken, though the company was still producing parts for steam cars as late as 1905.

The main motivation for the naphtha system was to simply to evade the USA regulations that required even the smallest steam launch to carry a qualified steam engineer; this stipulation was not lifted until 1912. Other countries had no such regulations , and the use of boiling petrol outside the USA was minimal. The naphtha engine did have some other advantages, They were lighter than an equivalent steam-launch and could be hoisted onto a medium-size steam yacht with davits; only the largest steam yachts could carry a steam launch. They could also be started from cold very much more quickly than a steam launch.

| Left: Cross-section of the Boiling-Petrol Launch

|

This thing was probably expensive to build: there is no such thing as a free launch.

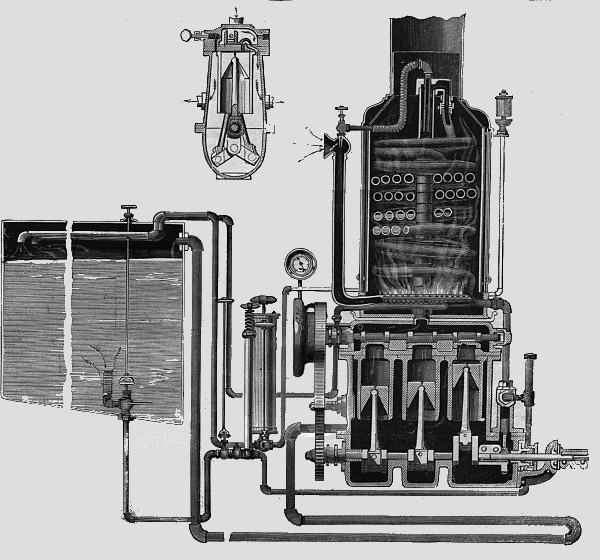

| Above: The Boiling Petrol System.

|

An interesting feature of this boiler-engine combination is that there is no throttle valve. With small steam launch engines with flash boilers it was quite practical to operate just using the reverse gear and the burner control, as the amount of working fluid in the boiler was very small, and the response to burner modulation therefore reasonably quick. The same applied to the boiling-petrol system.

| Left: Another View of The Boiling Petrol System

|

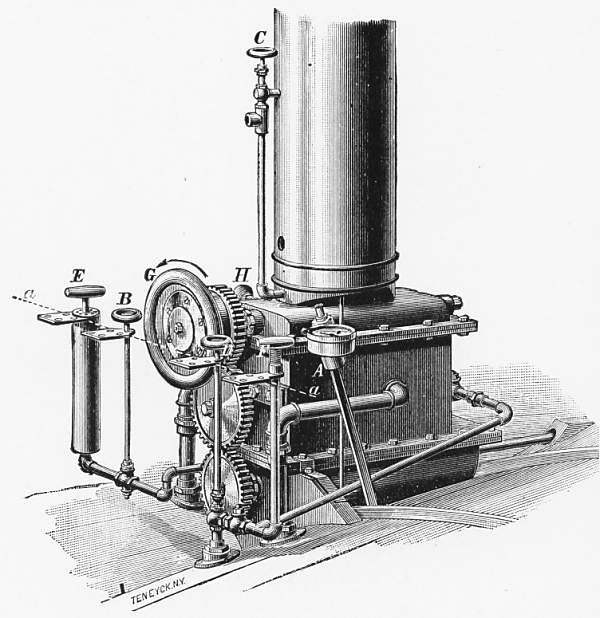

Left: The naphtha engine

|

Petrol consumption was said to be between 17 and 20 pints per hour, generating 6 horsepower at 233 rpm. The launch would carry two people at about 5.5 knots. The petrol acted as lubricant as well as working fluid, and it was said that "the density of the petroleum employed should be between 0.68 and 0.70. Below the former figure the petroleum does not lubricate satisfactorily, and above 0.70 it does not evaporate sufficiently rapidly." This seems like a very small range of density to specify in an age when the refining of petrol was very much in its infancy.

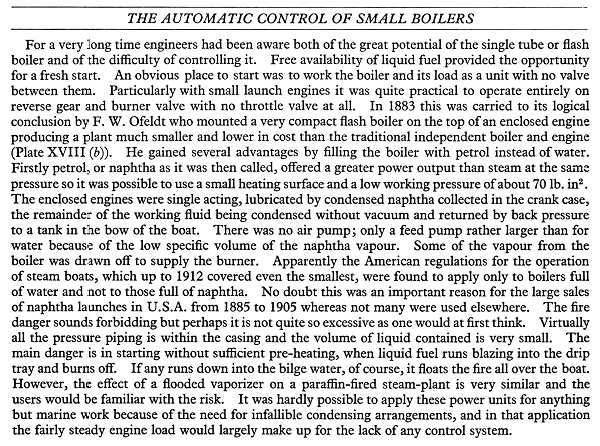

The dangers of this system hardly need enumerating. Most steam engines have little puffs of steam coming out of various crevices, such as the piston-rod packing. I see no reason why a petrol-boiling sytem should be any more leakproof, so it would seem to be only a matter of time before escaping petrol vapour was ignited by the nearby flame on the boiler, with dire consequences. J A Crabtree, writing for the Newcomen Society, was more optimistic, pointing out that there was a relatively small amount of petrol actually in the boiler, and the main risk was in starting without adequate pre-heating, when burning liquid fuel might run into the bottom of the burner casing and spill into the bottom of the boat. Crabtree states that anyone familiar with flooded vaporisers in paraffin-fired steam boilers would have been aware of the risks; this seems unduly complacent to me, as petrol and paraffin are very different in their flammability. Crabtree also says "It was hardly possible to apply these power-units for anything but marine work because of the need for infallible condensing arrangements." ie an ample supply of cold water to condense the petrol vapour. Working non-condensing was not an option because it would have meant total loss of the expensive naphtha, and the hazard of clouds of petrol vapour billowing out of an engine do not need underlining. Crabtree's comments are reproduced in full below.

Turning to the possibility of excessive boiler pressure, a steam boiler explosion is quite bad enough; a petrol boiler explosion would add conflagration to detonation and would be considerably more dangerous and destructive.

| Left: External View of The Boiler, with the engine under it

|

| Left: External View of The Boiler, with the engine under it

|

Here some rather terse instructions for starting up your naphtha launch:

"To start the engine: light alcohol lamp A, and set on rest plate, with tube inserted at bottom of retort; turn air valve B from left to right, give air pump E sufficient number of strokes to force gas from tank, through outlet pipe to burner, where flame from lamp ignites it and so heats retort. Use air pump one to two minutes in warm weather, but in cold weather much longer, as gas generates very slowly in the tank then. [1] Open wide naphtha valve D, and give five or ten strokes of naphtha pump F, which pumps naphtha from tank in bow to retort on top of engine, [2] and if retort has been sufficiently heated, the pressure will at once be indicated on gauge. Then open injector valve C, which supplies fuel to burner; after which turn reverse wheel G from right to left, or vice versa, a few times until engine will run itself. To increase pressure, after engine is started, give a few strokes with naphtha pump F, and open wide injector valve C.

"Regulate both speed and pressure by injector valve C- opening to increase, and closing to reduce speed. To go ahead turn reverse wheel G to left; to back, turn wheel to right. You can reverse instantly, and at full speed. Lamp can be taken out, extingished, and set on rest-plate with tube outside as soon as engine is running. H indicates safety valve. When landing it is only necessary to close injector C and naphtha valve D, fasten your boat, and no further attention is required.

"The "air pump" draws the gas from the tank to the burner and also to a whistle by turning valve B from right to left. [3] The naphtha valve should be left wide open to allow free circulation."

These instructions raise a few queries, referenced by the numbers in square brackets.

1] This seems to mean that petrol vapour is generated in the fuel tank, which can't be right. Or is 'gas' being use to mean gasoline, ie petrol? That nakes little sense either.

2] Petrol is initially forced out of the fuel tank to the boiler by air pressure; in which case what is this manual pump for? In normal operation the naphtha pump mounted on the crankshaft would have kept the fuel flowing.

3] The "air pump" does not draw the gas from the tank, it pushes liquid naphtha from the tank.

My final thought is when landing a boat (and I have done it many times with narrow-boats) you need a pretty rapid response to the throttle, particularly for slowing down by going into reverse. But as we have seen naphtha launches had no throttle and could only be controlled by modulating the burner. I wonder how fast that was in practice; it sounds very tricky to me.

| Left: A range of naphtha power plants

|

The information in this section comes from:

The Scientific American Supplement No 1104 of Feb 27, 1897, and No 1118 of June 5, 1897. It was supplemented on 7 Mar 2008 by info from "The Automatic Control of Small Boilers", a paper read to the Newcomen Society by J A Crabtree on 10 Mar 1971. Further information from the journal MotorBoating (Nov 1942, p46-48) in March 2015.

ARTICLES

The Scientific American said:

"These little boats have won for themselves an astonishing record. They seem to be as absolutely secure from accident as any kind of power driven craft can be. Every possible precaution is adopted..."

This seems an extraordinary conclusion to draw. There are many questions about how such a perilous technology came to get even limited acceptance. A sea-going experiment with ether as a working fluid came to a fiery end in 1855, long before the naphtha launches appeared.

| Left: A relatively modern view of the petrol launch and its safety problems: 1970

|

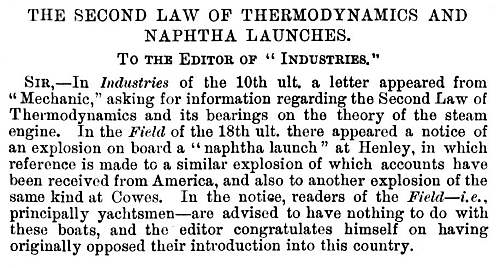

CONFLAGRATIONS AND EXPLOSIONS

| Left: News of naphtha launch explosions at Henley and Cowes: 1891

|

| Left: A naphtha launch goes up in 1910

|

| Left: A naphtha launch goes up in 1904

|

HISTORICAL NOTES

This is taken from a 1965 article called "Naphtha Launches" by F L Herreshoff in the journal Rudder, from the USA:

"Certainly as we look at the naphtha launch today it seems a most infernal machine. Strange to say, however, these launches had few explosions or fatal accidents 'though most of them blazoned up occasionally. Many were copper sheathed in the engine compartment so these blaze-ups were rather laughed at or thought to be part of the game... The real, and possibly the only reason for the naphtha launch was to get around the law that required a licenced engineer on a steam launch... The genius who worked up the naphtha power plant to evade the law was a German named F W Ofeldt of New York and I class him as a genius because he arranged or designed launches that had few serious accidents and because the power plants were novel and built at little expense... The naphtha launch was smaller, lighter, cheaper and, of course, much quicker starting than the steam launch. They sold like hot cakes right up to around 1900 when the internal combustion engine began to be reliable and lighter than the

naphtha ones."

Hopefully that extract is short enough to avoid copyright issues. I'm not at all sure about "few serious accidents".

From the Eagle Harbour website:

"The commentary on the smaller boat hulk was very interesting. My father who began to spend time at the Harbor in about 1905 always told the story that this boat was a "naphtha launch" that exploded and burned at a dock on the west end of the Harbor with several fatalities. It was later towed to the east end and sunk by the coast guard. As I recall he said that the boat was owned by a prominent copper country family."

Which sounds like the sort of accident that would be all too likely. Clearly this "blaze-up" was not a laughing matter.

An extract from a news report in 1900:

"July also featured the Larchmont Yacht Club "Race Week." Thursday, July 25th, was a scheduled break for the big sailing yachts and raceabouts. Rowing contests and three events for powered craft were scheduled in their place. No gas engine launches raced but the naphtha launches were

divided into two classes, those over 21 feet and those 21 feet and under; Intrepid took the over 21' title and Trochilus took the 21 and under title. The third race was for Alco-Vapor launches, launches

powered by alcohol vapor.

The development of the camp and cottage life which is now the great feature of the river has been made possible largely through the introduction of the older types of pleasure craft, first, the primitive steam launches, then the "naphtha launch," and the "Alco-vapor launch," and more recent years the gasoline launch with explosion motor." Note the rise of the internal-combustion engine.

This gives us a tantalising glimpse of another forgotten technology- the alcohol-vapor motor. This would presumably have been rather safer due to the lower flammability of alcohol vapour compared with naphtha. The Alco-Vapor engine was also invention of Frank W Ofeldt, after the naphtha engine, as noted above; it burned kerosene and boiled a mixture of water and alcohol, once again to circumvent the steam regulations. No doubt a ride in an Alco-Vapor launch with a few leaky joints was an intoxicating experience. The Museum of RetroTech now has a page specialising in alcohol motors

One of the users was Leo Hendrik Baekeland, the Belgian inventor of Bakelite. He was a keen yachtsman, and in 1899 purchased a gasoline launch. He successfully cruised from Yonkers up the Hudson, through the connecting waters to the St. Lawrence and back.

(Information from volume xxiv - eighth memoir of LEO HENDRIK BAEKELAND 1863 - 1944 by Charles F. Kettering)

This museum in the USA has what is said to be the only surviving Naphtha Launch: The Antique Boat Museum.

Naphtha launches faded away quickly when internal-combustion engines became a practical way to power boats. There was no need to carry the weight of a boiler, none of the hazards of boiling up petrol, and still no need for a licensed engineer. Also, it put the price of naphtha up.

NAPHTHA LAUNCHES IN FICTION

This is an extract from Tom Swift Among The Fire Fighters by "Victor Appleton", 1921. Our boy hero has been cruising around in his own airship, as you do, and lands to rescue the occupants of a sinking boat...

"But Tom Swift was too skillful a pilot to cause his craft to sustain much of a crash. He made an almost perfect "three point landing," and there would have been no unusual shaking, except for the fact that the field was a bit bumpy, and the craft more heavily laden than usual.

"Good work, Tom!" cried Ned, as the Lucifer slackened her speed, the young inventor having sent her around in a half circle so that she now faced the lake. Then Tom and Ned climbed from the cockpit, throwing off goggles and helmets as they ran to the shore where there were several rowboats moored.

"And a little old-fashioned naphtha launch! By all that's lucky!" cried Tom. "I didn't think they made these any more. If she only works now!"

There was a little dock at this point on the lake, and the boats appeared to be held at it for hire. But no one was in charge, and Tom and Ned made free with what they found. They considered they had this right in the emergency.

The naphtha launch was chained and padlocked to the dock, but using an oar Tom burst the chain.

"Get one of the rowboats and fasten it to the back of the launch!" Tom directed Ned. "I don't believe this craft will hold them all," and he nodded toward those aboard the sinking boat -- for it was only too plainly sinking now.

"All right!" voiced Ned. "I'm with you. Can you get that engine to work?"

"She's humming now," announced Tom, as he turned on the naphtha, and threw in a blazing match to ignite it, this act saving his hand. Naphtha engines are a trifle treacherous.

A few moments later, though not as quickly as a gasoline craft could have been gotten under way, Tom was steering the small launch out and away from the dock, and toward the craft whence came the faint calls for help. Behind them Tom and Ned towed a large rowboat.

Tom speeded the naphtha craft to its limit, and, fortunately for those in danger, it was a fast boat. In less time than they had thought possible, the young inventor and his chum were near the boat that was now low in the water--so low, in fact, that her rail was all but awash."

Note that "Naphtha engines are a trifle treacherous", if only when you light them up. There was a long series of Tom Swift books, written by ghostwriters and all credited to the publisher's house name of Victor Appleton.

NAPHTHA LAUNCH MODELLING

Some very fine work has been done by John Bentley.

|