Updated: 29 Nov 2015

BR87 added

The Luttermöller Axle Articulation System |

Updated: 29 Nov 2015 |

Dr Luttermöller was a director of the famous Orenstein & Kopplel locomotive works near Berlin. His method of articulation was superior to the Klein-Lindner axle because it could be used on locomotives with frames either inside or outside the wheels; the KL system was limited to outside frames.

The KL axles were heavy, and many railways preferred the Golsdorf system of sideplay on the driving axles.

The Luttermöller Axle Articulation System was a method for driving axles that could swivel to follow tight curves. Since such curves frequently occurred in mountainous areas it was vital to use as many axles for adhesion as possible. Many different methods for driving swiveling wheels by means of complex levers and linkages were evolved, two of the more successful being the Hagans and the Klose systems. There were plenty of wholly unsuccessful approaches, such as the Fink system.

However, none of these were very satisfactory in use, requiring excessive amounts of maintenance.

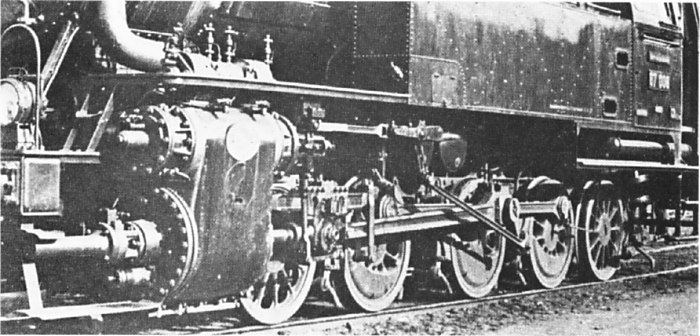

The gearcase swivelled as a unit with the leading/trailing axle, sideways movement being controlled by the return springs.

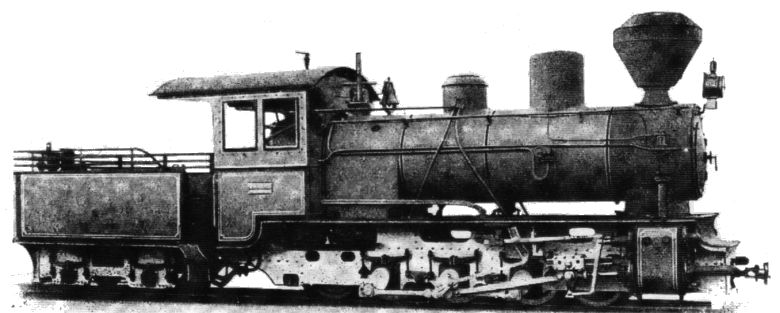

Only the middle three of the five driving wheels are coupled with external rods in the usual way. The first and fifth axles are driven by the gearing. Built by Orenstein & Koppel.

The Luttermöller System was used in many European states, and notably also on 0-10-0 locomotives working on sugar-cane plantations in Java. Rob Dickinson states that three were still working in 2002.

Above: The Luttermöller Geared Axle in plan view.

Above: The Luttermöller Geared Axle in plan view.

Above: An 0-10-0 tender locomotive with Luttermöller Axles at front and back; at first glance it looks like a 2-6-2. Built by Orenstein & Koppel.

Left: Deutsche Reiechsbahn BR 87 locomotive with Luttermöller axles: 1927