Updated: 12 Sep 2004

Uniflow Steam Engine Road Vehicles. |

Updated: 12 Sep 2004

|

THE ATKINSON STEAM WAGGON.

The Atkinson Steam Waggon Uniflow engine had relief valves

built into the pistons to relieve excessive compression of the exhaust steam. See "The Undertype Steam Road Waggon" by Maurice A. Kelly. (Goose & Son Publishers Ltd) The Atkinson was a very successful Uniflow engine, and is believed to be the only successful on-road uniflow design.

A 40 hp version in an articulated chassis was shown at the 1927 London Motor Show.

THE DOBLE UNIFLOW STEAM CAR ENGINE.

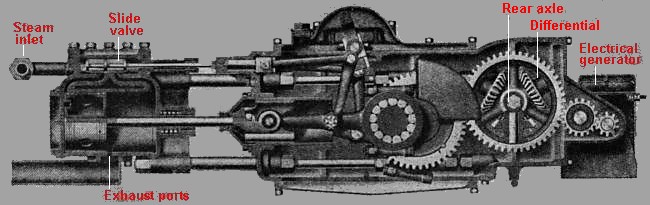

The Doble-Detroit steam car was the first commercially produced by Abner Doble, in association with the General Electric Company, in 1916. Manufacture of the car was stopped by the War Emergency Board after only thirty had been built. The engine was a two-cylinder double-acting uniflow design. The valve gear was a simplified form of Joy valvegear. Slide valves worked on a flat port face and could lift to release excessive compression. Four degrees of cutoff were provided, controlled by a foot pedal. These included 75% for starting and hills, 20 - 25% for normal running, and 12.5% for economical high-speed running. Cylinders were 5" bore by 4" stroke.

| Left: The Doble-Detroit Uniflow Engine.

|

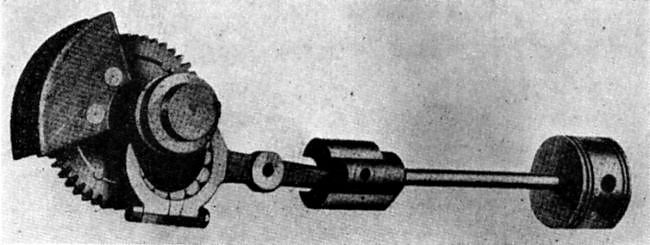

| Left: Piston, crosshead and crank of the engine.

|

| Left: Doble-Detroit Uniflow Engine. This the Fig 2 referred to below.

|

This is an extract from a paper presented by Abner Doble* at the Cleveland Section Meeting (though I am not sure of what) on October 20, 1916

* Vice-president, General Engineering Co.

"In order to have efficient working it is necessary to provide for high expansion. This can be obtained with a compound engine, but not satisfactorily, as the ratio of cylinder volumes has to be carefully determined in relation to the probable loads, speeds and steam-chest pressures. These conditions vary so widely that the single expansion engine, Fig. 2, is necessary.

To provide the high expansion desirable, with a simple noiseless valve gear and one valve per cylinder, it is imperative to use the uniflow principle. In the uniflow engine the valve takes care

of the steam inlet only, the exhaust passing out through ports at the end of the stroke when these are uncovered by the piston. It is thus possible to secure cut-off at 5 per cent of the stroke.

Since the thermal conditions in the uniflow cylinder are practically ideal, it is unnecessary to use superheated steam. This means that little cylinder lubrication is required, and the troubles

formerly caused by superheated steam are absent."

However... following experience with the Doble-Detroit double-acting engine, with no auxiliary exhaust valves to counter excessive compression, Abner Doble later said:

"The uniflow engine was found unsuited for use in a motor vehicle. Its economy in motor vehicle service was definitely less than the compound, it was heavier, uncertain in manoeuvring, apt to block on hills (due to the long compression), and undesirable for high speeds due to the very heavy long pistons. The early cut-off necessary to give sufficient expansion produced an irregular torque, quite unsuitable for a motor vehicle, as the torsional vibrations induced in the axle shafts proved extremely annoying and difficult to damp out. A multiplicity of cylinders, although a certain remedy, would lead to prohibitive cost."

THE CURRAN PROJECT

In 1928 a steam bus was tested in New York City. The power plant was designed by Frank J Curran, and used a water-tube boiler generating steam at 600psi to feed a three-cylinder uniflow engine. This was said to have "improved valve action which regulates cutoffs from full stroke to 5%". The bus was driven over various routes and inclines on the outskirts of New York, and was said to have averaged better than 8 miles per gallon.

Report from Scientific American, Jan 1928.

|