The Sentinel steam locomotives were British designs built by the Sentinel Waggon Works of Shrewsbury, England. They had squat vertical boilers and two-cylinder vertical steam engines connected to the wheels by chain drive. The unusual technology was derived directly from the Sentinel steam waggons, with little modification. This might sound like a bodge-job, but in fact the Sentinel locomotives used quite sophisticated steam technology, and were very successful for shunting operations and general industrial use. Their short wheel base meant they could negotiate tight curves, and their geared steam-motor design meant they gave no hammer-blow so light rails could be used. Standard Sentinels had a two-cylinder vertical engine giving 100HP. The recommended engine speed was 500rpm, with Sentinel setting a maximum of 600rpm, corresponding to a locomotive speed of 21mph. Typically, the engines were run at lower speeds around 300rpm which gave good fuel economy.

|

| Left: Sentinel vertical-boiler locomotive No 7109: 1927

This Sentinel locomotive is the former Croydon Gasworks Joyce, built in 1927 with Works No 7109. It is under restoration at the Somerset & Dorset Railway Heritage Trust at Midsomer Norton railway station. You can read about the restoration here.

Some Sentinel locomotives (believed to be eight in all) had this peculiar styling rather like two mobile pianos back-to-back.

|

Andy Chapman, who provided much help in putting this page together, and part-owner of No 7109, stands proudly by his '28-ton mistress'. This page could not have been completed without the generous help of Andy, who provided many of the images on this page.

|

| Left: Sentinel locomotive No 7109: the first move

On Thursday 18th Feb 2016, No 7109 moved under its own steam. You can see the YouTube video. This frame shows the engine just emerging from its shed.

Congratulations to all concerned in this brilliant feat of restoration.

|

Sentinel locomotives were textbook illustrations of adapting existing parts to make different designs. This example of a 200HP Sentinel was brought about simply by fitting two vertical engines instead of one. There is an engine behind each of the curved access doors at the front; each engine was rated at 100 HP. The middle section was taken up with a 600 gallon water tank, thus positioned so that as it emptied wheel adhesion would change in roughly the same way for each axle. This tank was a 4" thick casting up to the top of the casing- made deliberately heavy to increase adhesion. The inside of the large cab was mostly taken up by the water-tube boiler. It operated at 275 psi, quite a respectable pressure.

SENTINEL HISTORY

The first Sentinel steam locomotives appear to have been delivered in 1925.

The last two Sentinel steam locos were delivered in 1958. One of them, works No 9622, WAs at the the Teifi Valley Railway in South Wales It has since been moved to the Pontypool & Blaenavon Railway for restoration but is reportedly not currently in an operable condition.

According to Wikipedia there are no less than 32 preserved Sentinel locomotives in the UK. There are two double-engine Sentinels with Mobile Piano casings at the Amsted-Maxion Steel Works in Cruzeiro, Brazil, but only one was reported to be still working in 2012, and this appears to have ceased operation in 2014. Since the locomotives were delivered in 1930/31, 80 years of work is not a bad record. There is an excellent YouTube video of one of them in action. You can find more information on these two locomotives, and some very fine photographs, at the International Steam Pages website.

SENTINEL EXAMPLES

The steam locomotives built by Sentinel for the GWR, for the LMS, for the LNER, and other railways are listed on this Wikipedia page. A few of them are looked at in detail below.

|

| Left: Sentinel locomotive 47190: 195?

This is one of two Sentinels that were used for shunting on the Somerset and Dorset Joint Railway. (S&DJR)

At the 1923 Grouping, both Sentinels were integrated with London, Midland and Scottish Railway (LMS) stock in 1930 and renumbered as 7190 and 7191. After Nationalisation in 1948, they took British Railways numbers 47190 and 47191. Eventually both were shamefully scrapped.

The S&DJR Sentinels have a Wikipedia page.

|

|

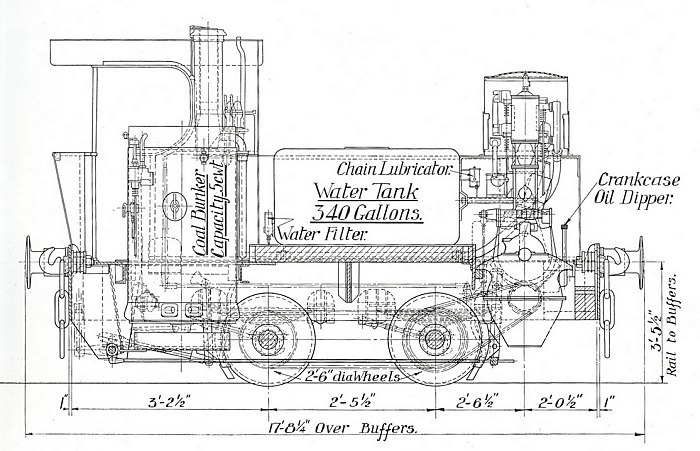

| Left: Sentinel dual-engine vertical-boiler locomotive: 1927

This shows the general construction of No 7109 above. The two vertical engines are mounted one behind the other, and the chain drive to the front axle. The two engines were spur-geared to a single shaft inside the gearbox at the front.

Drawing from the book Sentinel Patent Locomotives produced by the Sentinel Waggon Works in Dec 1931.

|

Each engine was a two-cylinder double-acting unit with poppet valves operated from separate inlet and exhaust camshafts. There were five settings for direction and cut-off, selected by sliding the camshafts axially.

There is more on the Sentinel designs on the Wikipedia Steam Motor page.

|

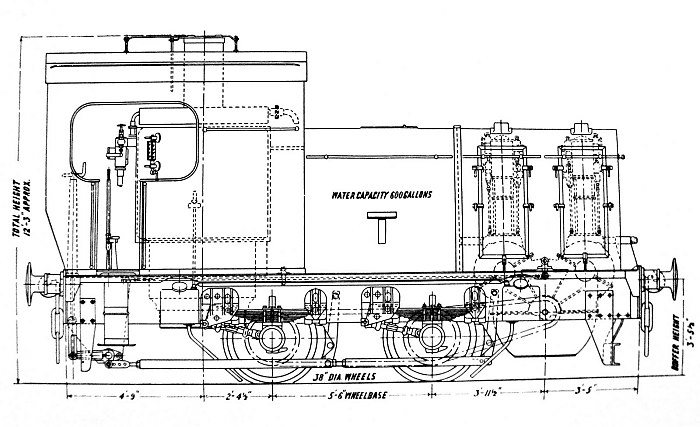

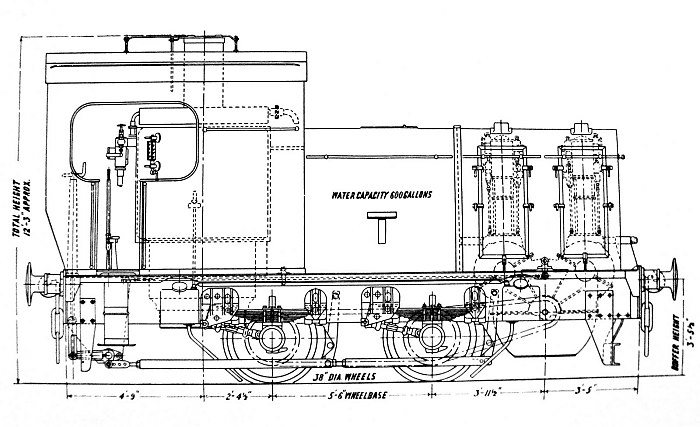

| Left: Sentinel vertical-boiler locomotive LNER type Y1: 1925-27

Twenty-four of these locomotives in standard gauge were built for the LNER from 1925 to 1927, and then passed on to British Railways in 1948. Unlike the dual-engine Sentinels, both the engine and the boiler were inside the cab.

Judging by the lion visible on the side, this picture of No 54 was taken after transfer to British railways.

Note that the vertical cylinder on the left is NOT the chimney- it is the filler for the water tank. The real chimney is just visible on the top of the roof to the right.

|

Rods can be seen running from the frame to the axle-boxes. This looks a bit like some sort of shaft-drive, but it is nothing of the kind. They are radius rods used to locate the axle position so that the spacing of the chain-wheels, and hence the chain tension, is correct.

|

| Left: Sentinel vertical-boiler locomotive LNER type Y1: 1925-27

Boiler pressure: 275 psi

Weight: usually about 20 tons

Fuel: coal

There is a Wikipedia page on the LNER Class Y1 which gives more complete technical specs.

|

Above drawing from the book Sentinel Patent Locomotives produced by the Sentinel Waggon Works in Dec 1931.

Note the load weights added to increase adhesion. On some Sentinels these were bolted to the frames to reinforce them. Another ingenious solution on the part of the Sentinel engineers!

|

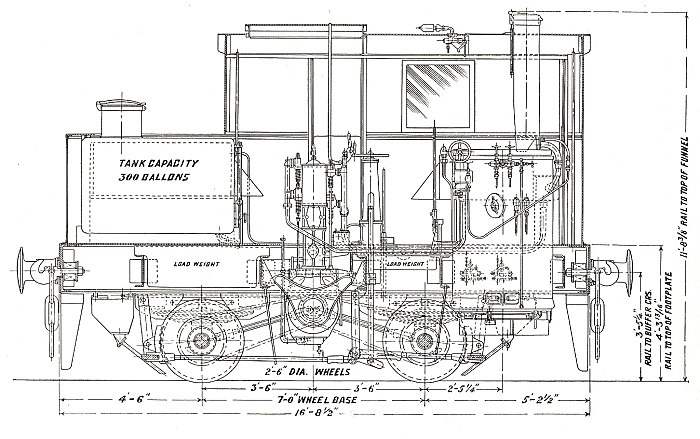

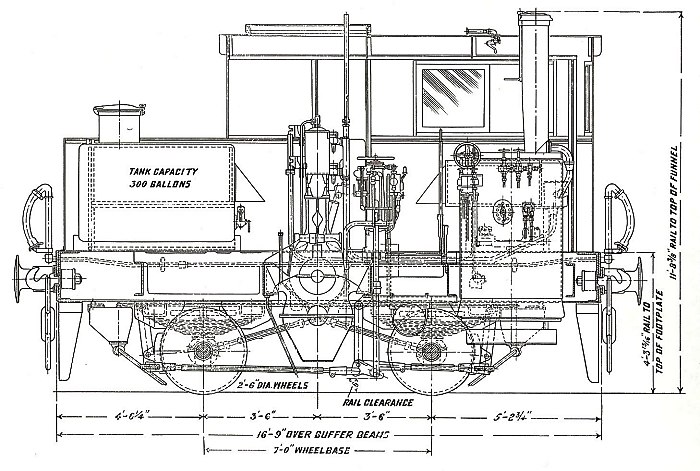

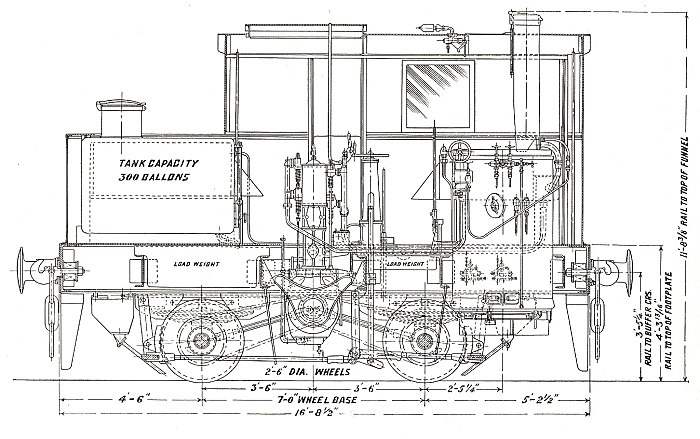

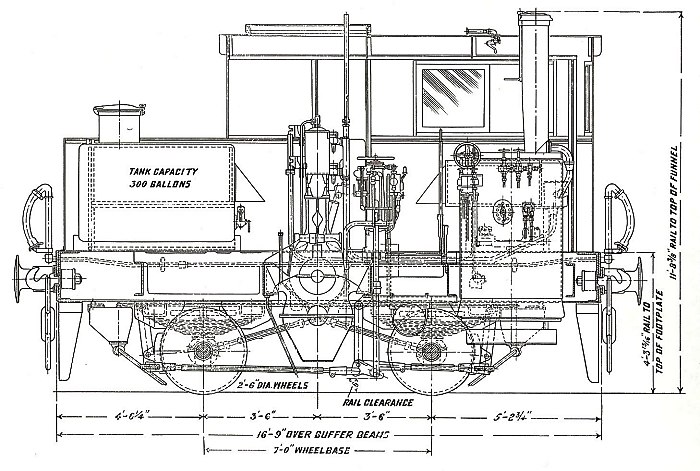

| Left: Sentinel vertical-boiler locomotive type Y3: 1927

The Y3 differed from the Y1 in that its engine was mounted higher up to make room for a two speed gearbox below the engine crankcase. Thus it was not only a powerful shunter but also a relatively swift mover when required. Thirty-two were built and delivered to the LNER in 1927.

Boiler pressure: 275 psi

Weight: not confirmed, but more than Y1 because of the gearbox.

Fuel: coal

There is a Wikipedia page on the LNER Class Y3 which gives more complete technical specs.

|

Above drawing from the book Sentinel Patent Locomotives produced by the Sentinel Waggon Works in Dec 1931.

|

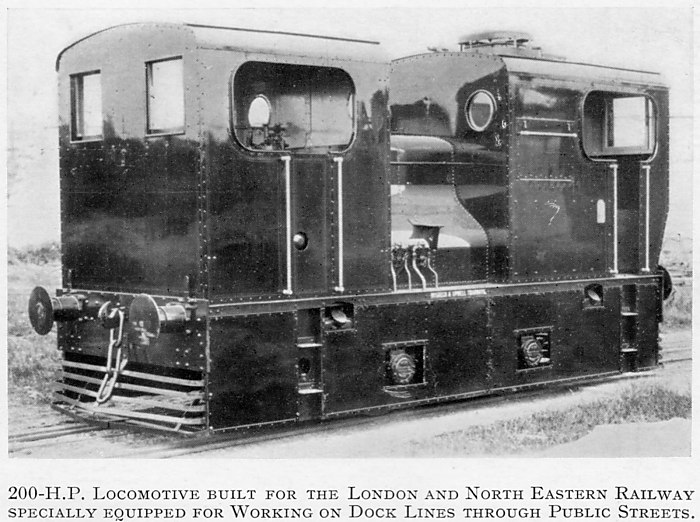

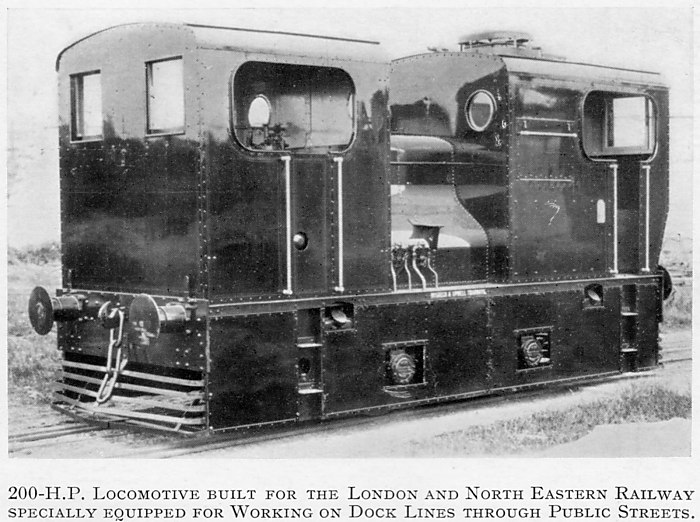

| Left: Sentinel vertical-boiler locomotive Type Y10: 1927

The Y10 was a double-cab twin-engine 200 HP version built for the LNER 1930. They were known as DEDG; Double-Engine Double-Geared, because they also had a gearbox giving two ratios. These could only be changed with the locomotive stationary.

Only two were built. They were modified to meet the regulations on locomotives working on public streets. The guard-rails below the buffers were to sweep hapless pedestrians aside and keep them from going under the locomotive, while the wheels and running-gear are fully enclosed. This was not only to stop Little Johnny getting tangled up in the moving parts, but probably also due to a long-held belief that horses found the sight of moving coupling-rods particularly upsetting. Note the little square holes giving access to the wheel bearings, while smaller apertures allow the sand boxes to be refilled.

|

There is a Wikipedia page on the LNER Class Y10 which gives more complete technical specs.

These locomotives were built in 1930, for service on the Wisbech and Upwell Tramway and had several tram engine features such as a cab at each end. The need for this expensive feature is currently obscure- tank engines travelled happily in both directions with only one cab. (Engines that can run in both directions are highly advantageous as costly turntables or land-occupying wyes are not required to turn the engine round at the end of each trip) However trams could be driven from each end so the Tramway regulations probably hold the answer.

Both cabs had full driving controls, but naturally the fireman had to stay at the end with the boiler.

These locomotives were not very successful during their career on the Wisbech and Upwell Tramway, for despite their 200 HP they found the freight loads too heavy, and frequently had to work flat-out, with a correspondingly high coal consumption. After trials at Ipswich docks both were transferred to Yarmouth in May 1931 to work the quayside line. Both were transferred to British Railways in 1948 but neither have survived.

Drawing from the book Sentinel Patent Locomotives produced by the Sentinel Waggon Works in Dec 1931.

SENTINEL TECHNOLOGY

.jpg) |

| Left: Typical Sentinel boiler for a one-engine locomotive, sectioned

This is a water-tube boiler; the tubes being sloped to promote the clearance of steam and the circulation of water. The firebox is completely surrounded by water. These boilers were designed for fast steam-raising.

This drawing demonstrates the tolerance of vertical boilers for working at an angle; even a gradient of 1 in 6 leaves the boiler in a very safe condition, ie with the shoulders of the inner shell well covered. This feature was very necessary for steam waggons that might ascend steep hills, but not really required for the locomotives. I don't think you're going to get a locomotive up a 1 in 6 gradient unless it's a rack locomotive.

Note the superheater coil and the exhaust drying box. The latter is a feature taken from the Sentinal road waggons; it reheated the exhaust steam to avoid it giving into a visible white plume as it left the chimney. It was a requirement of the Highways and Locomotives Act 1878 that engines should "consume their own smoke"; this stratagem does not of course consume any smoke as such, but presumably it did make the waggon less visually obvious. Having watched a few Sentinel waggons moving about on YouTube I'm left undecided if this feature really worked or not.

The boiler fire was fed from the top of the boiler; the lid with the handle was lifted and coal dropped down the central tube into the fire, making one-man operation feasible. It is really a quite sophisticated design.

The Sentinel boiler has its own Wikipedia page.

Drawing from the book Sentinel Patent Locomotives produced by the Sentinel Waggon Works in Dec 1931.

|

|

|

Above: The Sentinel two-cylinder engine sectioned

Both inlet and exhaust valves were of the poppet type, driven by long push-rods from two camshafts in the crankcase. These camshafts could be moved axially for reversing and to alter cut-off.

An important feature is the 'plenum' space just beneath each cylinder. These spaces were open to the air, and sealed off from both the cylinder and crankcase by stuffing boxes. Thus steam leaking through from the cylinder would condense in the outside world rather than in the crankcase, where it would have diluted the lubricating oil.

Drawing from the book Sentinel Patent Locomotives produced by the Sentinel Waggon Works in Dec 1931.

|

|

| Left: The Sentinel two-cylinder engine

External view of the engine.

Drawing from the book Sentinel Patent Locomotives produced by the Sentinel Waggon Works in Dec 1931.

|

UNUSUAL SENTINEL LOCOMOTIVES

While it could be argued that any Sentinel locomotive counts as unusual some were more unusual than others. Here's one example:

While the "Beckton Shoebox" was a unique conversion, further research has uncovered other examples of Sentinel locomotives hiding their engine in what appears to be a chimney.

|

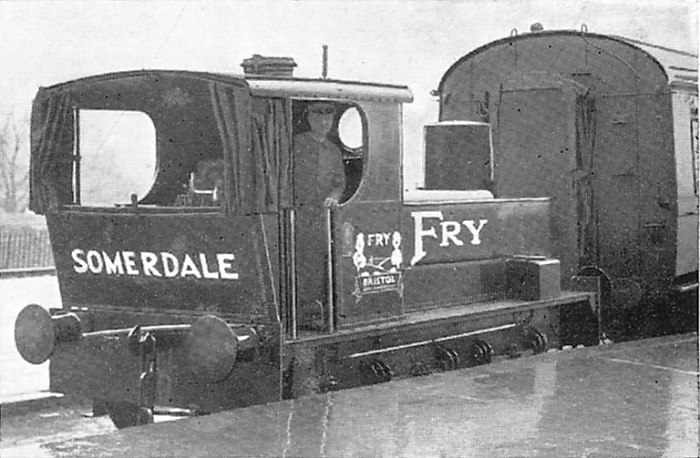

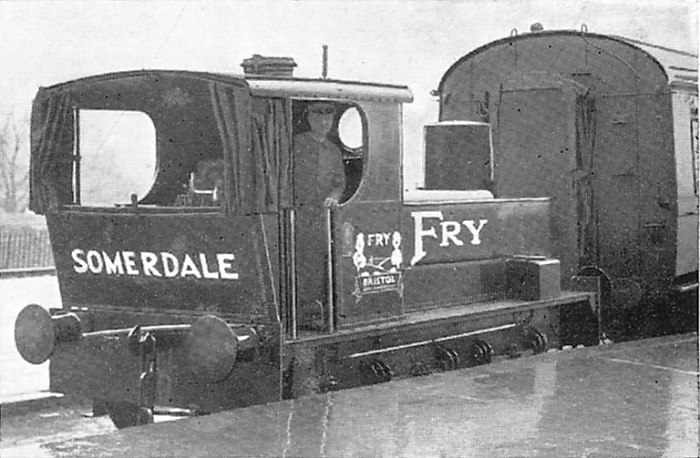

| Left: Fry 100HP Sentinel locomotive No 7492: 1928

This locomotive was built in 1928. It worked at Fry’s Somerdale chocolate factory from 1928 to about 1958. The engine is under a cylindrical cover at the front of the locomotive.

|

|

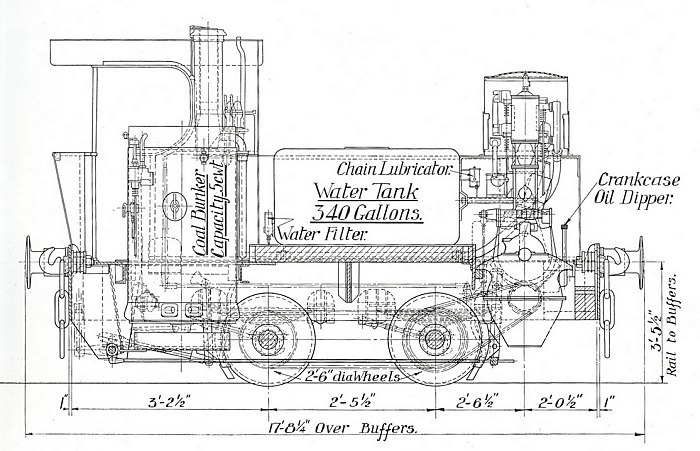

| Left: The Fry 100HP Sentinel locomotive No 7492: 1928

Note the large size of the water tank, which extended almost the full width of the locomotive. Sentinels usually had big water tanks in relation to the rest of the machinery. Some versions were able to work for 16 hours without taking on water. The central location kept the weight distribution between the two sets of wheels constant as the water level varied. Since a UK gallon of water weighs 10 pounds, a full tank would have weighed 1.5 tons, which would have materially helped with wheel adhesion.

In this case the engine drives the front axle, which is coupled by chain to the rear axle, instead of by coupling rods. None of the Fry photos show the chain-coupling, because it was inside the frames. At least one Sentinel was built with outside chain coupling; see No 8024 below.

|

19:02 13/04/2016

|

| Left: The Fry 100HP Sentinel locomotive No 7492: 1928

A picture taken when the locomotive was nearly new. It is not very clear in these pictures, but it appears that the engine cover was cylindrical, and not rectangular like the Beckton Shoebox.

|

|

| Left: The Fry 100HP Sentinel locomotive No 7492: 1928

7492 in dire straits in a scrapyard. But Help Is On The Way; the Fry locomotive is currently being restored at The Avon Valley Railway.

|

More information on the Fry locomotive and its place of work can be found in:

A report by the Keynsham Voice

A report by the Bath Chronicle.

|

| Left: The Fry 100HP Sentinel locomotive No 7492: 1928

No 7492 on the way to restoration. The boiler is at the left, the enormous water tank in the centre, and the vertical engine on the right.

|

|

| Left: The Fry 100HP Sentinel locomotive No 7492: 1928

No 7492 on the way to restoration. The vertical engine is covered with a bag, while the cylindrical engine housing is on top of the water ta.

|

|

| Left: 100HP Sentinel locomotive No 8024 with chain coupling: built 1929

This is the only picture found so far of a Sentinel with outside chain-coupling between the driving axles. Inside chains would seem to be more desirable for safety reasons. It is Sentinel Works No 8024 built in 1929 and known as 'Gasbag' because it worked shunting coal waggons for Cambridge gasworks. There was an eccentric arrangement in which coal was shunted into a gas-engine driven tippler, which loaded a shuttle-service of lorries which took the coal across the main Newmarket road and into the gas-works. There is much more info on the truly excellent Disused Stations site.

The locomotive has been preserved and is seen here at the

Ribble Steam Railway in Lancashire.

|

|

| Left: 100HP Sentinel locomotive No 8024 at Cambridge: 1960s

Apart from the chain-coupling, this version is also unlike other Sentinels in that it has a cylindrical water tank, and the engine is inside an arch-shaped housing.

The water-tank filler could be mistaken for an undersized steam dome, and all-in-all it is a confusing locomotive for the unwary.

I have attempted to contact Phantasrail Galleries to get permission to use this photograph, but the website seems dead.

|

SURVIVING SENTINELS

There are believed to be 39 surviving Sentinels, around the world, which is really a quite an impressive number. The official list of survivors is here.

.jpg)