Gallery opened: 18 Nov 2005

Updated: 9 Apr 2022

Polygonisation Today added

Locomotives with Non-Circular Wheels |

Gallery opened: 18 Nov 2005 |

There's no point in pretending that this is going to be a large gallery in the Museum. Locomotives with non-circular wheels have always been something of a minority taste.

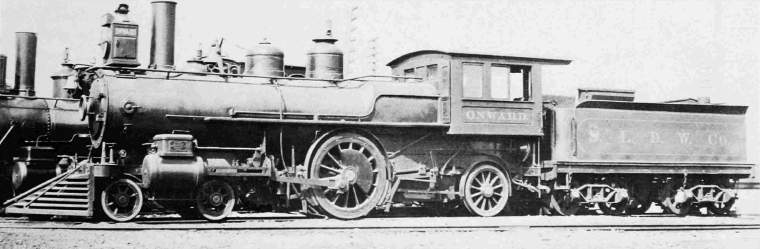

In 1887, in the USA, the Swinerton Locomotive Driving Wheel Company took delivery of a unique locomotive confidently called "Onward" built by the Hinkley Locomotive Works of Boston. Its unique feature was that its wheels were not round.

C E Swinterton specifed that each driving wheel should actually be a polygon with 118 sides, each segment being about 2 inches long. The theory behind this quite daft arrangement was that the line contact at the intersection of each segment would have better rail adhesion than a circular wheel, which was supposed to have only a point contact; this is not of course actually the case as even steel deforms under enough pressure, so there is on fact a contact area even with a circular wheel.

| Left: The Swinerton Locomotive "Onward"

|

The Swinerton Locomotive had a single driving axle, (an arrangement long abandoned elsewhere because of its poor adhesion) chosen presumably to emphasise the effectiveness of the invention. The "Onward" was tried on several north-eastern lines, but worked about as well as you would think it would, and failed to convince practical railway men that it had any special advantages. It was sold to the Portland and Rochester Railroad- after the polygonal driving wheels had been replaced with conventional ones. After a few years the P & R sent it to the Manchester Locomotive Works for reconstruction as an ordinary eight-wheeler. "Onward" was cut up for scrap in 1905.

No other hard information on the performance of the polygon wheels has so far been unearthed, but it seems very probable that the non-constant radius would have caused very severe vibration. It also seems likely to destroy brake-blocks very quickly- there is clearly a brake-block acting on the single driver in the photograph above.

Another disadvantage- like we need one- is that polygonal wheels must have been very expensive to make. Circular wheels can of course have their periphery turned true on a lathe very easily. There is also the question of wear; I would have thought that the sharp corners would blunt rather quickly, and you would need to keep taking a file to the wheels to "sharpen" them. Great fun!

A quotation from "Locomotive Engineering" Volume IX, February 1896, page 194

"Some mechanical fallacies are very hard to kill out. We supposed that the Swinerton polygonal wheel had lost its grip, but we find out by a newspaper notice that the company which controls this peculiar invention are struggling to force it into use for street-car service. We understand that the Lobdell Wheel Co. are making cast-iron chilled wheels after the Swinerton design for street-car service. We hope they will be able to demonstrate more value for the thing than what surface railroads were able to do."

The Lobdell Wheel Company was by 1867 the world's largest manufacturer of railroad wheels with 300 full time employees.

POLYGONAL WHEELS TODAY

Nobody deliberately makes polygonal wheels today- but they can make themselves, due to wear. See the report here.

Here's an excerpt from the introduction to the paper:

"Shortly after the ICE1 high-speed train was put into operation in Germany, a polygonisation phenomenon was observed to occur on the wheel tread, causing noise in the frequency range of 70–100 Hz and also resulting in medium-frequency structural vibration of the car body. To reduce the wheel–rail rolling noise and vehicle structure vibration, solid wheels were replaced by rubber-sprung ones. However, fatigue failure of a rubber-sprung wheel caused a derailment accident in Eschede, Germany, in 1998 [1]. The results of the accident investigation showed that the rubber wheels exhibited polygonisation with two harmonics around the wheel circumference. This can lead to a violently fluctuating wheel–rail contact load, and the wheel rim may fracture under alternating loads." |

Polygonal wheels are no laughing matter.

|