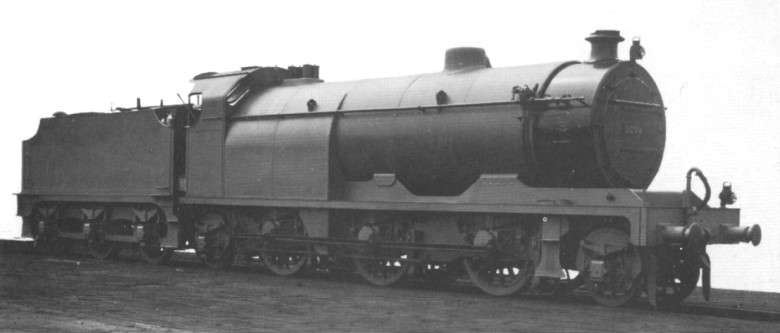

Cecil Walter Paget was born in 1874 and died in 1936. He was the son of the Midland Railway Chairman, George Ernest Paget. When the project began in 1907 Paget was works manager of the Derby Shops of the Midland, but the design was built initially at his own expense, but with financial assistance from the railway when it proved more expensive than estimated. It was a 2-6-2 with a firebrick firebox and eight inside cylinders, with rotary valves operated a longitudinal shaft driven by outside fly cranks. The engine and tender weighed 122.9 tons in working order. It was no light-weight.

Paget's locomotive was completed in January, 1909, and made steaming trials soon afterwards. There were immediate problems with differential expansion taking place between the cast-iron rotary valve body and the bronze liner which controlled the cut-off. As an expedient the working clearances were increased until the valvegear leaked like a sieve when cold but was reasonably steam-tight after warming up.

On one occasion the speed of 82 mph is claimed to have been reached, but this was never officially confirmed. It worked several test trains down to London and up to Manchester, but in 1912 a rotary valve seized up solid at Syston. The main line was blocked for seven hours, and this sort of disruption was not lightly forgiven; without considering conspiracy theories, this sort of thing gives a locomotive a bad reputation, and may have had something to do with its ignominious end.

|

| Left: The Paget Locomotive: side elevation and plan.

|

The Paget was propelled by eight single-acting uniflow cylinders, arranged in two groups of four with a rotary valve above each group. Two cylinders drove the front axle, four drove the middle axle, and two the rear. There were (as far as I can see) no auxiliary exhaust valves, which were often found necessary with the uniflow system.

Extensive testing of the rotary valvegear showed it absorbed 30% more power than the D-type slide valve.

The drive for the valvegear was taken from the coupled driving axles by two extra coupling rods driving cranks at the rear. A gearbox under the cab allowed for reversal.The machinery was designed to rotate at 450 rpm at 80 mph.

The balancing of this design was reported as virtually perfect, with very little hammer-blow on the rails and no vibration. In this respect at least, Paget had succeeded.

After its embarrassing seizure, the locomotive was laid up until 1918, when it was scrapped while Paget was in France commanding the Royal Engineers Railway Operating Department. It has often been hinted that the forces of reaction waited until the designer's back was turned before destroying his creation, but this remains unproven.

|

| Left: The Achilles-Heel of the Paget Locomotive: the rotary valvegear for steam admission.

An apparently generous supply of lubrication nipples did not prevent frequent seizure of the inner sleeve or liner.

|

The lower shaft continuously rotated the central valve element. The liner was rotated by gearing from the upper notch-up shaft to alter the cut-off timing.

|

| Left: The Paget Locomotive: cross section and end view of the firebox.

Two firedoors were provided. This was because at 55 sq ft, the grate area was the largest in Britain.

|

|

| Left: The Paget Locomotive: The firebox brickwork and the "firebridge".

|

The firebox was also innovative; there was no "waterwall" at the sides or rear, eliminating complicated staying. The firebox was 11ft 10.5in long, almost as long as the boiler, and was lined with 6 in of firebricks. It was fitted with a "firebridge" instead of the usual arch. Unlike most attempts to use firebricks on locomotives, this appears to have been largely successful, though there were still some problems with bricks cracking and falling out.