Few details available but research continues...

|

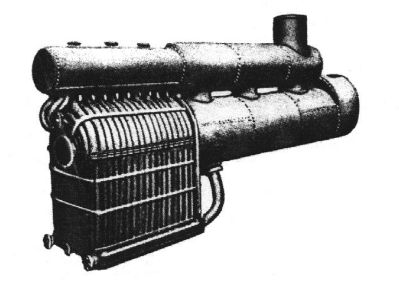

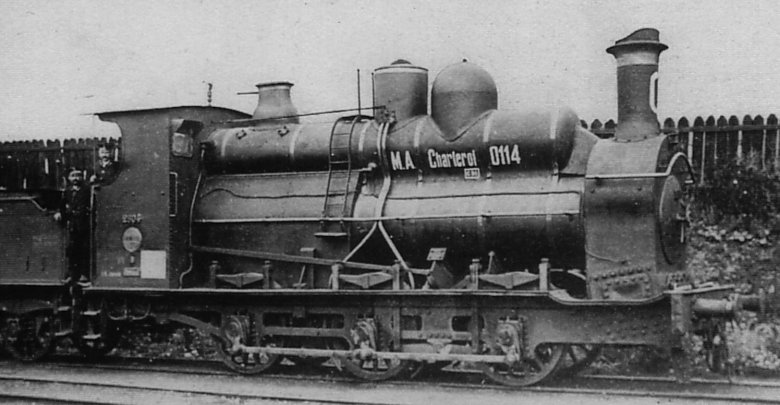

| Left: Austrian 0-6-0 goods Brotan built 1900-1910.

Note the pipe coming out of the front of the steam drum. This was probably the steam passage from the regulator to the cylinders, and apparently passed through the smokebox.

|

|

| Left: Austrian 0-6-0 Brotan, as above.

Apologies for poor picture quality.

|

|

| Left: Austrian 0-6-0 Brotan, as above.

Note the single water-gauge on the rear of the top steam drum. This is very strange, because the water gauge is the most important thing in the cab, and its failure could be literally fatal. I am astonished that nobody made the effort to fit in two; I can see no reason why it could not be done.

|

BROTAN BOILERS IN GERMANY: 1940.

In 1940 the need for a powerful locomotive with an axle load of about 18 tonnes became evident. Many lines could take an 18 tonne loading, but not the 20 tonnes of the existing Class 44 locomotive. The result was the BR 42, a 1'E (2-10-0) machine for heavy haulage, and design work was complete by December 1942. Two BR 42 prototypes were fitted with Brotan boilers, supposedly providing:

1) A weight saving of 3 tonnes.

2) A saving of 500 man-hours manufacturing time

3) A longer permissible periods between boiler maintenance.

Locomotives BR 50 3011 and 50 3012 were also built with Brotans, and it was intended to use them in more 50s and 42s. The snag was that on the Eastern Front maintenance was sporadic and water quality abysmal; in this conditions the Brotan boilers showed a 100% failure rate. No more were built.

BROTAN BOILERS IN HUNGARY: 1914-19

Hungary was by far the biggest user of Brotan boilers, but information seems to be hard to come by, possibly because of the language barrier. Here is what I have found; if there any errors do please contact me.

The big advantage of the Brotan boilers was that they used less copper, as the firebox was constructed from steel tubes rather than copper sheets. This was very attractive for Hungarian locomotive builders, as Hungary had very limited copper reserves. The Hungarian state railway MÁV set up an experimental project, and a few locomotives were rebuilt with Brotan boilers in the early 1900's. They were from the locomotive Classes 222, 325, 326 and 377; the most common types. The Class 11 locomotives, a very small design with a 2-2-0 wheel arrangement, was built using Brotan boilers exclusively.

Before 1914 two Hungarian Class 326 locomotives were rebuilt using the original Brotan boilers design, for evaluation. They were not wholly satisfactory, and were rebuilt with conventional boilers in the 1920's.

All Hungarian steam engines between 1914 and 1921 were built with Brotan-Defner boilers. Those locomotives, originally designed and built before the First World War, were rebuilt with Brotan boilers. These were Classes 324, 375 and 376.

All of the new Classes- 601, 342, 328 and 442- were only built with Brotan boilers. An exception is Class 342, where the two prototypes built in 1913 had copper firebox boilers, but the production version engines were all equipped with Brotan boilers. After WW1 both prototypes were given to neighbouring countries, so only Brotan boilered Class 342s remained in Hungary.

|

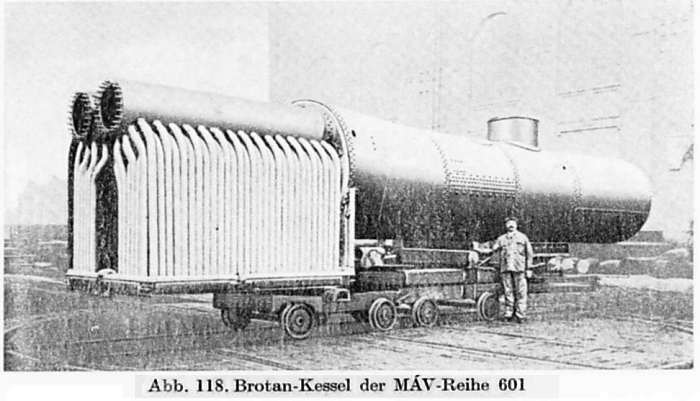

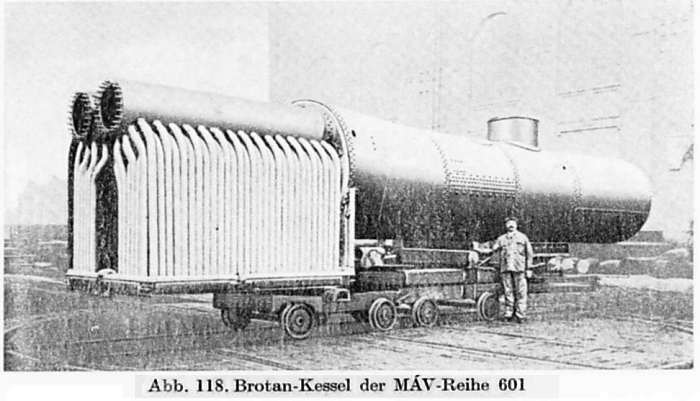

| Left: Brotan boiler for a Class-601 MÁV locomotive

For ten years or so the 601 class were the most powerful locomotives in Europe, at 2360 HP, and the boiler was correspondingly large. Eventually their power was exceeded by German locomotives of the 01 and 44 classes.

This is the only Brotan boiler with dual steam drums found so far.

|

|

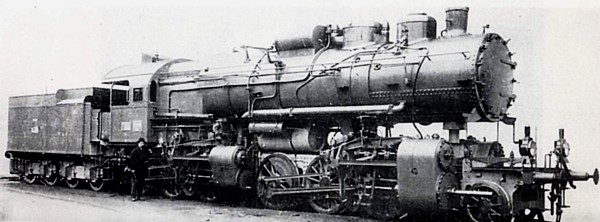

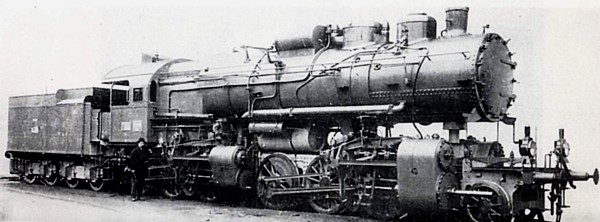

| Left: Class-601 MÁV locomotive

The Class-601 was a Mallet articulated locomotive, with the wheel arrangement 2-6-6-0, built for the Hungarian State Railway (MÁV) from 1915 onwards. It was a four cylinder compound, with the low pressure cylinders on the swivelling section at the front. Schmidt superheating was fitted.

The 601 Class has its own Wikipedia page.

Regrettably no example has been preserved.

|

The Class 651 Mallet locomotives built for MÁV all had conventional copper fireboxes, but the private company KsOD ordered similar locomotives in 1913 that were equipped with Brotan boilers.

Despite the heavy committment to the technology, Brotan boilered locomotives came to be considered less powerful than their sisters with conventional boilers, and this was proven by trials in the 1920s. Thus after the First World War those Brotan boilered locomotives in of Classes with numerous copper firebox engines, like 324, 375 and 376, were rebuilt with conventional boilers at their major workshop overhauls in the 1930s and 1950s. Even so, a few Brotan boilered members of these Classes survived until the end of the steam era.

Those Classes that were exclusively Brotan boilered were not rebuilt; they kept this interesting feature for their whole lifetime. Neighbouring countries were more active, and they usually rebuilt their inherited Brotan boilered engines. MÁV sold 20 Class 328 engines to the Czechoslovakian CSD, there they were rebuilt with copper firebox boilers in the late 1920s. Some of these engines remained in Hungary after WW2, and became the only Class 328s with copper fireboxes.

The locomotives built in 1914 and 1919 by KsOd received Brotan boilers because of the lack of copper in wartime conditions.

|

| Left: A preserved Hungarian Class 375 locomotive after rebuilding with a conventional boiler

The Class 375 had a 2-6-2 layout. They were first built in 1908 to replace obsolete engines use in branch line operation. The class had astonishing longevity, the last steam locomotive built for MÁV in Hungary was Class 375 No 1032, constructed in 1958. Naturally there were many improvements and design changes during during the fifty years.

Picture kindly provided by Karap Krisztián Jan 2007

|

|

| Left: A Brotan boiler.

The Class of locomotive this boiler comes from is not currently known, but 601 is ruled out because there is only one steam drum.

Picture kindly provided by Karap Krisztián Jan 2007

|

|

| Left: Firehole and rear wall of the Brotan boiler.

Taken from inside the firebox looking out.

Picture kindly provided by Karap Krisztián Jan 2007

|

|

| Left: Underside of the steam drum of the Brotan boiler.

Taken from inside the firebox, looking to the rear.

Picture kindly provided by Karap Krisztián Jan 2007

|

|

| Left: The rear of the steam drum of the Brotan boiler.

The fittings have all been removed.

Picture kindly provided by Karap Krisztián Jan 2007

|

This company: www.mavnosztalgia.hu repairs and runs the preserved steam locomotives in Hungary, but none of them are Brotans.

Today all the remaining locomotives with Brotan boilers are plinthed and unsteamable. MÁV still has the tools to repair the conventional copper firebox boilers of the museum stock, but the Brotan boilers require special tooling, especially for fixing the vertical steel tubes into the upper steam drum and the bottom square tube.

BROTAN BOILERS IN RUSSIA: 1904-06

The locomotive engineer E Noltein of the Moscow-Kazan Railway was an early advocate of watertube fireboxes and began experiments in the late 1890s. The appearance of the Brotan water tube boiler prompted him to advocate fitting Brotan fireboxes to a number of locomotives as a trial.

After some bureaucratic delays, construction of two experimental boilers for 0-8-0 goods locomotives began in 1904. One was fitted to locomotive AH No 447. After two years of trials, Noltein claimed lower repair costs, which met his main aim, and fuel savings of 14.8% were also recorded. However, as usual, the complexities were found to outweigh the theoretical benefits, and AH No 447 was later converted back to a conventional boiler.

THE TROUBLED BROTAN.

This is an extract from a paper by Dipl-Ing Gaspar Szontagh in the Transactions of The Newcomen Society: "Brotan and Brotan-Deffner Type Fireboxes and Boilers applied to Steam Locomotives". See Vol. 62, 1990-91, pages 21-51:

"The construction of the Brotan water tube boiler is well known. The

side walls of the firebox are replaced by large water tubes. The

upper end of these tubes are fixed in one or two drums communicating

with the barrel. The lower ends are fastened into a hollow

foundation ring. This is also connected at the barrel. In this way

free circulation of the water in the firebox tubes is assured. The

barrel is of the orthodox type, excepting that the firebox tubeplate

is circular like the smokebox tubeplate.

"The Brotan boiler is well designed and steams freely on account of

the water tube firebox; the steam produced, however, is wetter than

in an ordinary boiler. The efficiency of the boiler is good and from

tests carried out by the Polish State Railways the consumption of

fuel in a Brotan boiler is about 5% less than in a boiler of orthodox

type.

"Compared with the ordinary firebox the junction between the

foundation ring and the barrel is less rigid and contains a certain

number of parts where the metal is affected by alternating stresses

caused by expansion and by vibration, which causes fatigue of the

material. The cracks which develop at these places make it necessary

to replace the parts in question after a relatively short time. It

is also difficult to keep the water tubes permanently tight in the

steam drums.

"The defects are for the most part developed:

a) in the corners of the lower part of the firebox tubeplate

b) around the openings in the firebox tubeplate which are

riveted to the steam drum

c) in the water tubes

d) on the circumference of the steam drum.

"Leakage is apt to develop at the following points:

a) rivets around firebox tubeplate

b) rivets between steam drum and the boiler barrel

c) where the water tubes enter the steam drum

d) connections between the foundation ring and the barrel.

The water tubes of the Brotan boiler require frequent scaling,

especially where the feed water is not good, and this requires

special scaling tools."

These observations are typical of the problems that dogged all attempts to use water-tube boilers in steam locomotives. The assembly of pipes and headers- which worked very well in stationary applications- was simply too vulnerable to the flexure and vibration of a locomotive pounding along a none-too-level track.